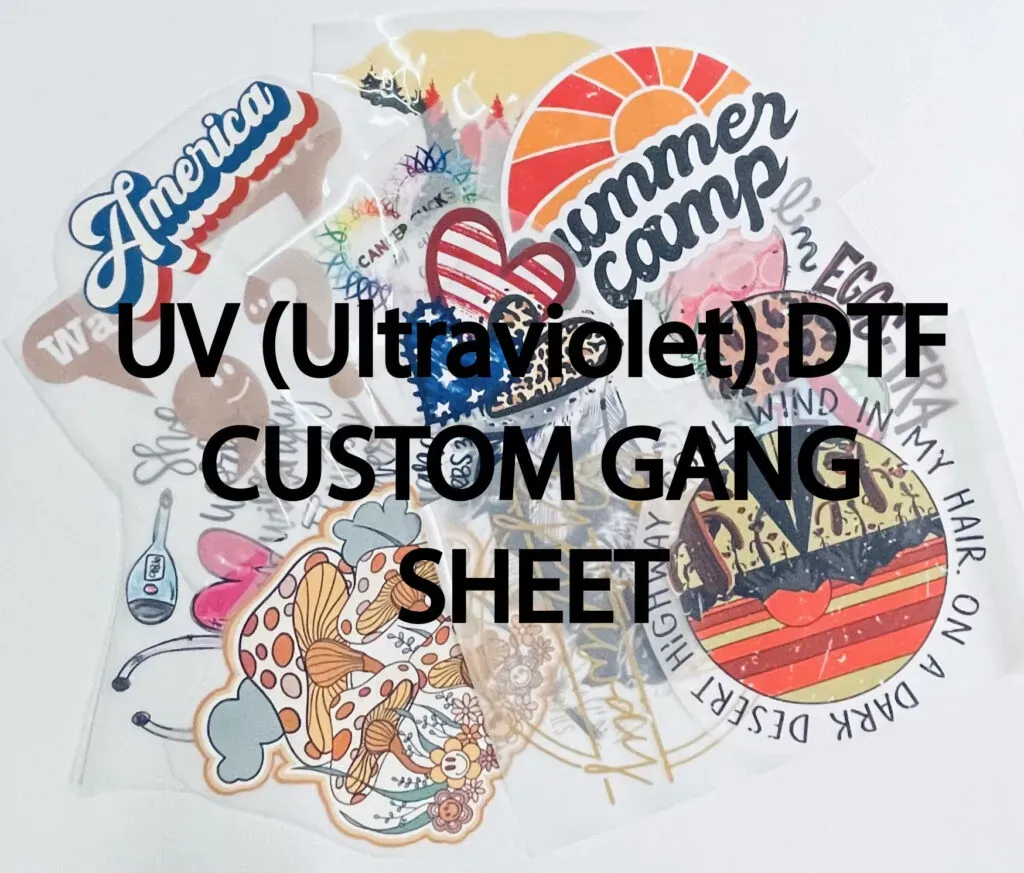

In the ever-evolving textile industry, **UV DTF Gangheet** is making waves as a revolutionary fabric printing technology. This innovative method merges the precision of UV printing with the versatility of Direct-to-Film (DTF), allowing manufacturers to achieve high-quality, customizable prints swiftly and sustainably. As businesses strive to adapt to consumer demands for unique and eco-friendly products, UV DTF Gangheet stands out by enhancing customization capabilities in textiles while minimizing environmental impact. By opting for this advanced printing solution, companies can optimize production efficiency and better meet the fast-paced requirements of the market. In this blog post, we will explore how UV DTF Gangheet is transforming the fabric printing landscape and paving the way for sustainable textile practices.

Known also as the hybrid Direct-to-Film and UV printing solution, the UV DTF Gangheet technique is at the forefront of innovation in fabric printing. This advanced technology provides a seamless integration of techniques that cater to the growing need for personalization in textiles. As the textile sector increasingly embraces digital textile printing methods, the adoption of UV DTF Gangheet enhances not only the speed of production but also contributes to sustainable textile practices by reducing waste. With a focus on customization in textiles, manufacturers can now offer an array of designs without the traditional limitations imposed by older printing methods. Ultimately, this evolution in the textile industry underscores the importance of blending modern technology with eco-conscious practices.

The Evolution of Fabric Printing Technologies

The textile industry is experiencing a technological renaissance, particularly in the realm of fabric printing. Innovations such as rotary screen printing, dye-sublimation, and now the hybrid UV DTF Gangheet are transforming how we perceive textile customization and quality. These advancements not only enhance the visual appeal of fabrics but also optimize production processes, paving the way for faster turnaround times and unmatched precision. As a result, manufacturers in the textile sector are empowered to respond to consumer demands for unique designs and sustainable practices.

Furthermore, the evolution of fabric printing technologies is reshaping the expectations of the end consumer. Today’s shoppers are more informed and have a keen interest in the techniques used to produce their clothing. They favor brands that embrace cutting-edge methods, particularly those that prioritize environmental considerations. With UV DTF Gangheet, manufacturers can deliver vibrantly printed fabrics while reducing their carbon footprint, aligning with the growing trend towards sustainability in the fashion industry.

Sustainable Practices in Digital Textile Printing

Sustainability is now at the forefront of the textile industry’s innovations, particularly in digital textile printing. The emergence of eco-friendly materials coupled with technologies such as UV DTF Gangheet enables manufacturers to minimize waste and energy consumption. This technology reduces the need for water-intensive processes and harmful chemicals traditionally used in fabric printing, which aligns perfectly with modern sustainable textile practices.

Moreover, as consumers become more aware of their purchasing choices, they seek brands that demonstrate a commitment to sustainability. The use of UV DTF Gangheet not only caters to this demand by providing high-quality prints but also enhances the brand’s reputation as an environmentally-conscious business. By moving towards sustainable practices, textile manufacturers can appeal to a broader audience, ultimately cultivating loyalty and trust among their consumers.

The Importance of Customization in Textiles

Customization is increasingly critical to consumer satisfaction in the textile industry. With the advent of technologies like UV DTF Gangheet, manufacturers can now cater to the specific needs of their clients quickly and efficiently. The ability to print bespoke designs without significant setup time translates to greater flexibility, enabling brands to respond swiftly to changing trends and consumer preferences.

In addition, as customization becomes a standard expectation from consumers, UV DTF Gangheet allows for intricate and detailed printing on various fabrics. This capability fosters creativity among designers who can experiment with diverse patterns and colorways. Such flexibility amplifies brand uniqueness and provides a competitive edge in a crowded market, ultimately boosting customer engagement and sales.

Benefits of UV DTF Gangheet for Manufacturers

UV DTF Gangheet technology combines the advantages of UV printing with the versatility of Direct-to-Film processes, offering manufacturers a plethora of benefits. High-quality prints produced at remarkable speeds are just the tip of the iceberg. This method also supports a broader range of fabric choices, including synthetics, which expands possibilities for fabric printing.

Moreover, manufacturers utilizing UV DTF Gangheet can benefit from lower production costs due to reduced material waste and minimized energy consumption. These factors lead to not only increased profitability but also the ability to sustain operations in a competitive landscape. The combination of efficiency and quality that this technology provides empowers manufacturers to take on larger projects while maintaining high standards, a critical requirement as market pressures escalate.

Competitive Advantages in the Fashion Industry

In the fast-paced realm of fashion, agility is crucial. Companies that adopt UV DTF Gangheet technology gain a significant advantage by being able to offer unique products at competitive prices. This print technology allows for quick adaptation to trends, enabling manufacturers to launch new collections more frequently and meet the demands of seasonal markets.

Additionally, with the growing consumer emphasis on bespoke options, businesses that can deliver customized products swiftly are at a distinct advantage. UV DTF Gangheet not only meets this demand but does so while maintaining exceptional quality standards. This proactive approach enables manufacturers to stand out in a saturated industry, fostering greater brand loyalty and improving market position through innovation.

Future Trends in Textile Printing

As the textile industry continues to innovate, the future of fabric printing looks promising—especially with technologies such as UV DTF Gangheet at the helm. Anticipated trends include further advancements in automation and artificial intelligence to streamline printing processes, as well as the development of even more sustainable materials. These factors stand to enhance the customization and speed of textile production while adhering to eco-friendly practices.

Also, as digital printing becomes increasingly prevalent, more brands will likely invest in technologies that allow for on-demand fabric printing. This trend delivers significant cost savings and reduces inventory waste, aligning perfectly with the sustainable goals of the industry. As manufacturers explore and incorporate new technologies like UV DTF Gangheet, they position themselves favorably to not only meet but exceed future consumer expectations in both quality and sustainability.

Frequently Asked Questions

What is UV DTF Gangheet and how does it impact fabric printing in the textile industry?

UV DTF Gangheet is an innovative printing technology that combines UV printing and Direct-to-Film (DTF) processes. It transforms fabric printing in the textile industry by offering high-quality, detailed prints quickly and efficiently. This technology enhances customization options, streamlines production, and minimizes waste, aligning with modern sustainable textile practices.

How does UV DTF Gangheet contribute to sustainable textile practices?

UV DTF Gangheet contributes to sustainable textile practices by reducing chemical waste and energy consumption during the printing process. By utilizing this technology, manufacturers can lower their environmental impact while meeting the growing consumer demand for eco-friendly products, making it a crucial choice in today’s textile market.

Can UV DTF Gangheet technology be used for custom fabric printing?

Yes, UV DTF Gangheet technology is excellent for custom fabric printing. It allows designers and manufacturers to create bespoke designs rapidly and efficiently, overcoming traditional printing barriers such as long setup times and high costs, and thus fostering greater innovation and flexibility in fabric customization.

What advantages does UV DTF Gangheet offer over traditional fabric printing methods?

UV DTF Gangheet offers several advantages over traditional fabric printing, such as superior print quality, faster production speeds, and greater customization capabilities. This hybrid technology reduces waste and enhances efficiency, making it a more attractive option for manufacturers in the competitive textile industry.

How does the implementation of UV DTF Gangheet benefit manufacturers in the textile industry?

Implementing UV DTF Gangheet benefits manufacturers by allowing them to produce high-quality prints at lower costs and with greater speed. This technology not only improves production capabilities but also provides a significant competitive edge by enabling manufacturers to respond quickly to evolving fashion trends and consumer demands.

What role does UV DTF Gangheet play in enhancing the quality of textile production?

UV DTF Gangheet plays a crucial role in enhancing the quality of textile production by delivering vibrant, detailed prints on various fabric types efficiently. By integrating advanced UV printing with DTF technology, it minimizes production downtime and optimizes output quality, positioning it as a preferred choice among modern fabric manufacturers.

| Key Points | Details |

|---|---|

| Introduction of UV DTF Gangheet | A hybrid of UV printing and Direct-to-Film (DTF) that enhances fabric printing efficiency and sustainability. |

| Revolutionizing Textile Printing | Combines advantages of UV printing’s quality and accuracy with the flexibility of DTF, facilitating quick fulfillment of fashion trends. |

| Efficiency and Quality | Speeds up production while maintaining high-quality output, aligning with sustainability goals by reducing waste. |

| Customization | Allows for rapid and cost-effective bespoke designs compared to traditional methods. |

| Sustainability | Lowers energy usage and chemical waste, aligning with consumer demand for sustainable practices. |

| Competitive Advantage | Manufacturers adopting this technology gain a significant edge by providing superior products efficiently. |

Summary

UV DTF Gangheet is redefining the landscape of the textile industry, melding advanced technology with pressing market needs. This innovative hybrid of UV printing and Direct-to-Film techniques is not only boosting production efficiency and quality but also prioritizing sustainability and customization, essential aspects in today’s eco-conscious fashion world. As UV DTF Gangheet technology continues to evolve, it becomes increasingly critical for manufacturers to integrate these solutions into their operations, ensuring they remain competitive and responsive to modern consumer demands. The future of fabric printing looks brighter with UV DTF Gangheet leading the way.