In the dynamic world of custom apparel printing, DTF transfers have emerged as a revolutionary method that combines innovation and quality. This advanced printing technique, known as Direct to Film, offers significant advantages over traditional screen printing, making it a favored choice for businesses looking to enhance their product offerings. With its ability to provide vibrant colors and intricate designs, DTF printing allows for a level of detail that is often unattainable with conventional methods. As we explore the nuances of print methods comparison, particularly DTF vs screen printing, it’s clear that understanding these differences is essential for making informed decisions in today’s competitive market. Dive into the world of DTF transfers to discover how this transformative technology can facilitate your custom apparel endeavors.

When examining the latest advances in textile printing, one cannot overlook the potential of Direct to Film transfers. This cutting-edge method stands out in the landscape of fabric decoration, providing unique solutions for apparel businesses. Unlike traditional techniques, such as screen printing, which can be limited by setup costs and fabric compatibility, DTF printing shows remarkable versatility and affordability. The industry is witnessing a growing trend toward custom printing solutions that cater to diverse consumer needs, and DTF transfers are at the forefront of this evolution. By embracing these innovative print methods, businesses can capitalize on opportunities that were once restricted by outdated practices.

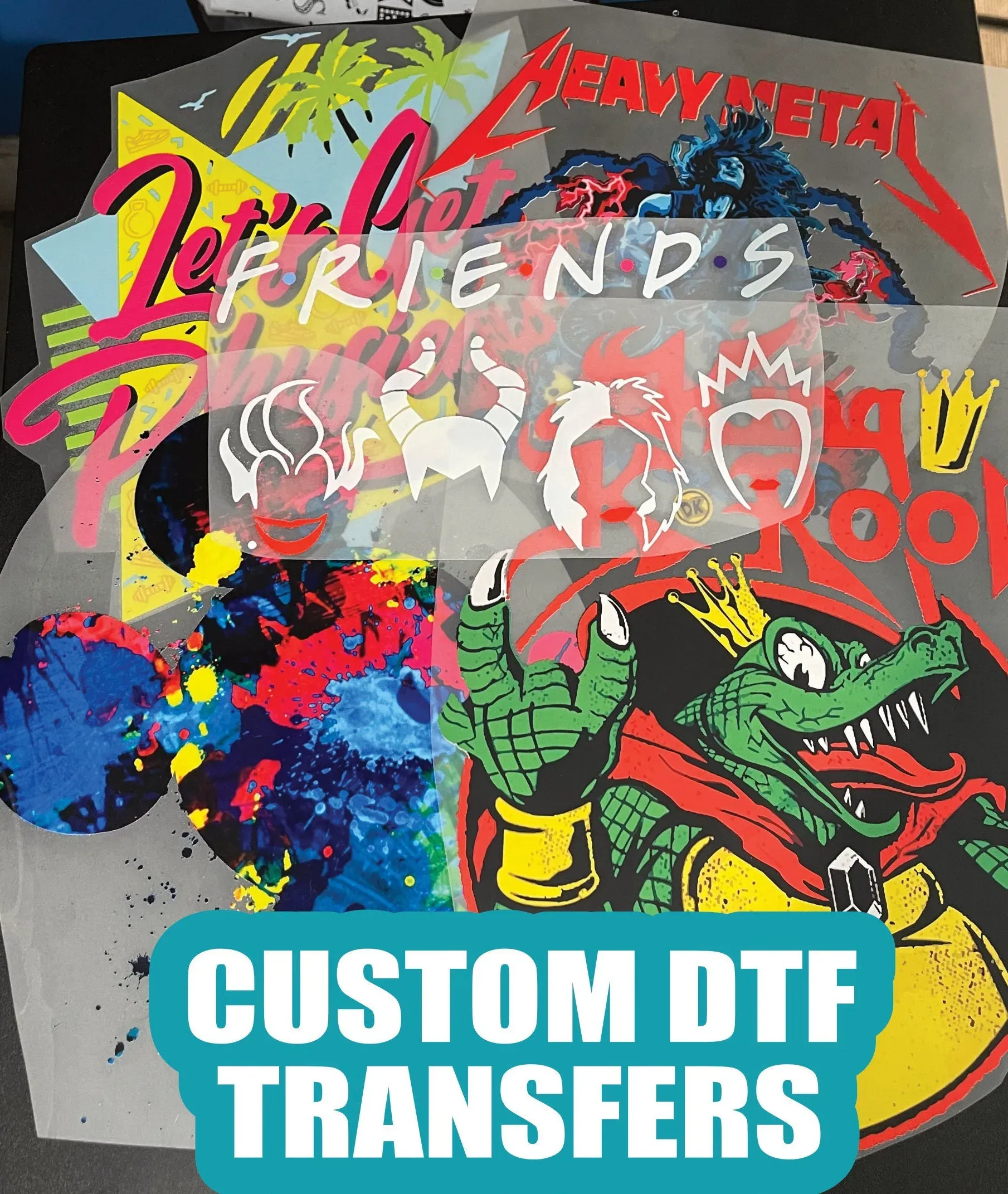

Exploring the Dynamics of DTF Transfers

DTF Transfers offer an innovative solution for businesses venturing into the world of custom apparel printing. This unique method employs a specialized process where designs are printed onto a film, which is then heat-transferred onto the fabric. The result is a high-quality, vibrant print that boasts impressive durability, making it a favorite among graphic designers and print shops. By utilizing DTF technology, companies can easily explore complex designs and varied color schemes that were often unattainable with traditional methods, thereby embracing creativity while catering to a broader market.

Unlike traditional screen printing, which typically requires significant setup and can be cost-prohibitive for smaller runs, DTF transfers excel in providing versatility and cost-effectiveness. This flexibility is particularly beneficial for startups and small businesses looking to test new designs without the burden of high initial investments in equipment. DTF Transfers enable these businesses to respond quickly to market trends, making timely modifications to their design approach and production output.

The Comparative Advantages of DTF vs Screen Printing

When comparing DTF transfers to the age-old method of screen printing, it becomes evident that both have their unique advantages. DTF printing stands out due to its low overhead cost for small runs, allowing businesses to produce high-quality prints without committing to large batches. This capability is particularly advantageous for custom apparel printing, where demand can fluctuate significantly based on trends or seasons. Screen printing, while effective for larger orders, can often leave businesses struggling with waste and increased costs for shorter production runs.

Furthermore, DTF printing surpasses screen printing in terms of detail and color accuracy. DTF transfers can achieve remarkable vibrancy and precision with intricate designs, catering to complex graphics that might be challenging with traditional screen printing. This advantage opens up a world of creative possibilities for brands that want to stand out with unique, visually striking apparel that resonates with their audience.

Maximizing Custom Apparel Potential with DTF Printing

DTF printing not only supports diverse designs but also breaks through the limitations often faced with traditional screen printing. Businesses can utilize DTF transfers on a wide range of fabrics, including cotton, polyester, and even blends, making it suitable for various products beyond just clothing. This adaptability allows entrepreneurs to explore new markets, such as home goods, sporting gear, or promotional items, giving them a competitive edge to meet diverse consumer needs.

Moreover, the absence of a minimum order requirement with DTF transfers fosters greater agility in production. Business owners can confidently fulfill custom requests or limited-edition items without the fear of stagnant inventory that larger minimum orders entail. This freedom encourages a more dynamic and responsive market strategy, allowing companies to align their offerings closely with consumer preferences and trends.

Evaluating Cost-Effectiveness in Printing Solutions

Cost is a critical factor when it comes to choosing between DTF transfers and traditional screen printing. With screen printing’s substantial initial investment in equipment and materials, many businesses may find themselves constrained, particularly if they are just starting. On the other hand, DTF printing allows for budget-friendly printing solutions that cater to both small and larger orders. This manageable approach to costs can empower businesses to invest more in creative development and marketing rather than being consumed by production expenses.

Additionally, DTF transfers minimize material wastage, as the process is designed for flexibility, accommodating different quantities based on demand. This efficiency translates directly into savings, enabling companies to allocate resources more effectively. Business owners can maintain a leaner operation, streamline their workflows, and still achieve high-quality output, making DTF an attractive choice for those prioritizing cost management alongside quality.

Navigating the Latest Printing Technology Innovations

The advancements in DTF printing technology are rapidly shaping the future of custom apparel. As innovations emerge, such as Sam’s DTF Transfers, which provide in-house solutions for screen printers, companies are now able to expand their service offerings without hefty machinery costs. This shift not only modernizes the printing landscape but also fosters competition within the industry, spurring further innovations that benefit end-users.

Insta Graphic Systems’ introduction of new DTF heat transfer products highlights a significant market trend towards enhanced durability and color vibrancy. Such technology improvements are evidence of DTF printing’s viability as a long-term solution for businesses aiming to meet higher consumer standards. Staying abreast of these advancements ensures that print shops can continually evolve their techniques, leading to improved consistency and quality in every print.

Conclusion: Choosing the Right Method for Your Business

As the printing sector continues to evolve, weighing the pros and cons of DTF transfers versus traditional screen printing is essential for businesses aiming for growth. While DTF printing offers numerous advantages such as cost-effectiveness and versatility, traditional methods still hold their value for larger orders. The right choice will largely depend on a business’s specific needs, production capabilities, and target market.

Ultimately, becoming familiar with various techniques and developments in the industry enables companies to pivot effectively as consumer demands shift. By understanding the strengths of each printing method and integrating the latest technologies, businesses can position themselves to thrive, adapt, and make informed choices that will enhance their market presence in the competitive landscape of custom apparel.

Frequently Asked Questions

What are DTF Transfers and how do they compare to screen printing?

DTF Transfers, or Direct to Film transfers, are an advanced custom apparel printing method known for their vibrant colors and high detail. In comparison to traditional screen printing, DTF transfers offer better flexibility across various fabrics, allow for no minimum order requirements, and are cost-effective for small runs, making them an attractive option for businesses looking for creative printing solutions.

What advantages do DTF printing methods offer for custom apparel printing?

DTF printing methods provide several advantages for custom apparel printing, including superior detail and color quality, the ability to print on a wide range of fabrics, and cost efficiency for smaller orders. This makes DTF transfers an optimal choice for businesses wanting to produce unique designs without the constraints of minimum order quantities, often associated with traditional screen printing.

Can DTF Transfers be used on different types of fabrics?

Yes, DTF Transfers are highly versatile and can be used on a variety of fabrics, including cotton, polyester, and blends. Unlike traditional screen printing, which may face limitations with certain materials, DTF printing adapts well to different textiles, making it an excellent option for businesses looking to diversify their product offerings.

How do DTF Transfers perform in terms of cost-effectiveness compared to screen printing?

DTF Transfers are often more cost-effective than screen printing, especially for small batch sizes. Traditional screen printing involves high setup costs that can make it financially unfeasible for smaller runs. With DTF printing, businesses can print small quantities without incurring excessive costs, providing a more budget-friendly solution for custom apparel printing.

What challenges do traditional printing methods like screen printing face compared to DTF Transfers?

Traditional printing methods such as screen printing face several challenges that DTF Transfers overcome. These include high setup and equipment costs, inefficiency in producing small runs, and limited compatibility with various fabrics. DTF printing eliminates these hurdles, allowing for greater flexibility and efficiency in custom apparel production.

What are the latest developments in DTF Transfers and the printing industry?

Recent developments in DTF Transfers have seen companies like Sam’s DTF Transfers providing premium in-house services, allowing screen printers to update their offerings without significant machinery investments. Additionally, products from Insta Graphic Systems showcase advancements in durability and vibrancy, reflecting a growing trend towards integrating the innovative aspects of DTF printing with traditional methods.

| Aspect | DTF Transfers | Traditional Methods (Screen Printing) |

|---|---|---|

| Cost-Effectiveness for Small Runs | Ideal for small batches with low setup costs. | High setup costs limit small quantity printing. |

| High Detail and Color Quality | Produces vibrant prints and fine details efficiently. | Struggles to achieve the same level of vibrancy. |

| Flexibility Across Fabrics | Compatible with a variety of fabrics, including blends. | Limited fabric compatibility, often restricted to cotton. |

| No Minimum Order Requirement | No need for large inventories; custom jobs welcome. | Often requires bulk orders to be efficient. |

Summary

DTF Transfers represent a significant advancement in the printing industry, offering businesses a modern alternative to traditional printing methods. This innovative approach is particularly beneficial for companies looking to create customized apparel with minimal upfront costs, exceptional quality, and diverse fabric compatibility. As more businesses migrate towards the flexible and efficient capabilities of DTF Transfers, understanding their advantages allows for strategic decision-making in a competitive market. By embracing DTF technology, businesses not only meet contemporary consumer demands but also enhance their creative potential.