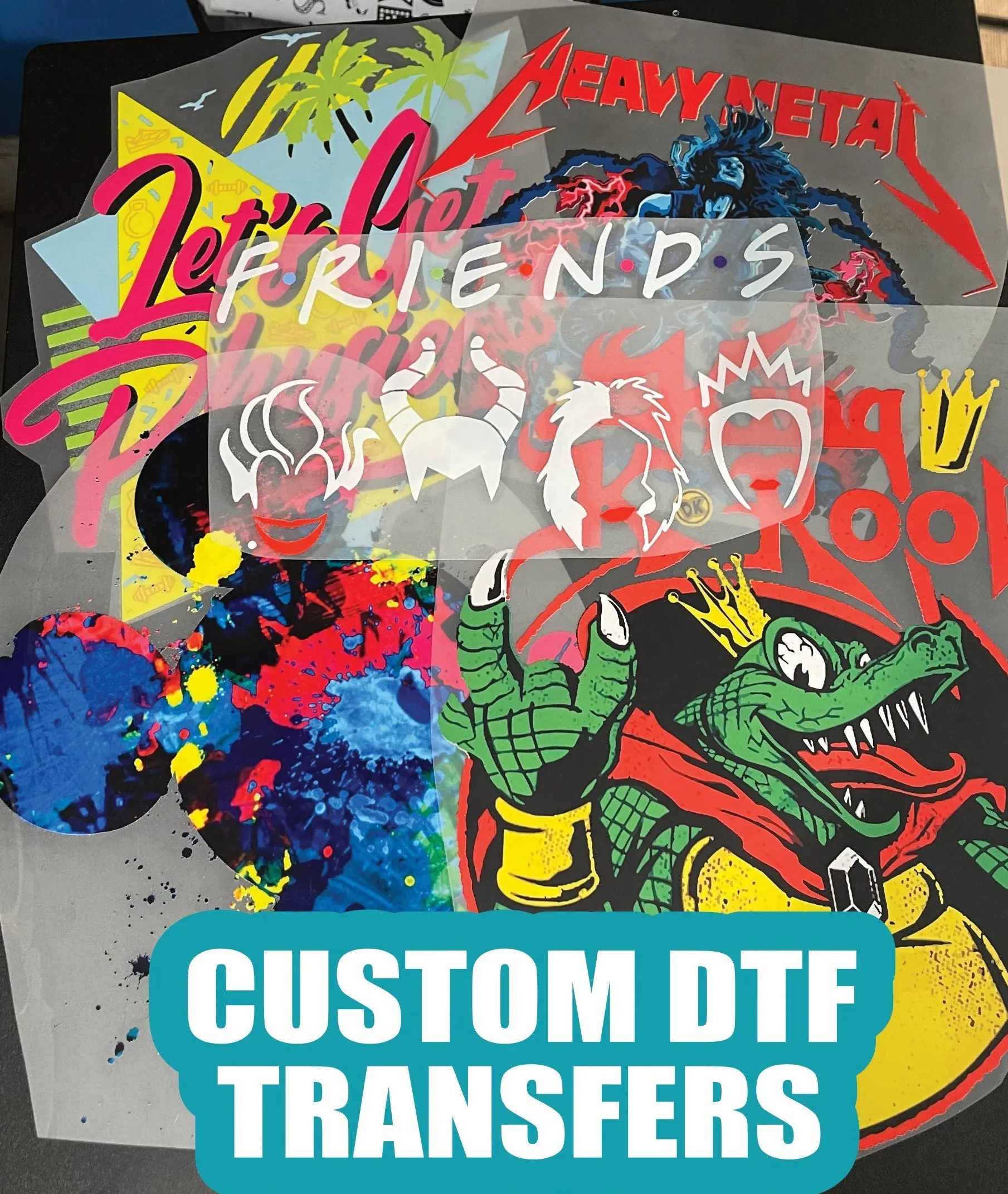

DTF transfers, or Direct-to-Film transfers, are revolutionizing the world of fabric printing, becoming a go-to choice for businesses and consumers alike. This cutting-edge technology allows for stunning custom apparel with vibrant colors and intricate designs that were once difficult to achieve with traditional methods. As the demand for sustainable fashion rises, DTF printing technology stands out for its environmentally-friendly materials and reduced waste, making it a popular choice in the industry. The versatility of DTF transfers to work with a range of fabrics enhances its appeal, enabling the creation of high-quality garments tailored for every occasion. In this post, we’ll delve into the dynamics of DTF transfer popularity and explore how it shapes the future of the fabric printing landscape.

Direct-to-Film printing is an innovative approach that has recently gained traction, particularly in the realms of custom fabric applications and personalized garments. This modern technique, which allows for detailed designs to be heat-transferred from film directly onto various substrates, offers an exciting alternative to traditional printing methods. The surge in popularity for this method coincides with the growing focus on sustainability within the fashion industry, as it generates fewer harmful emissions compared to older processes. Moreover, the capability to print high-resolution images makes it a favorite among brands seeking to provide unique apparel options. This introductory exploration will uncover the nuances and advantages of DTF printing, ensuring a comprehensive understanding of its transformative impact on fabric printing.

What is DTF Printing Technology?

DTF, or Direct-to-Film printing, is a revolutionary method in fabric printing that enables the application of custom designs through a unique transfer process. This technique involves printing high-quality images onto a special film substrate using advanced inkjet technology. Once the design is on the film, it is transferred onto the desired fabric with the application of heat and pressure. This method is particularly advantageous for achieving vivid prints on a wide variety of materials, including cotton and polyester blends.

The fundamental characteristics of DTF printing technology make it an attractive choice for businesses looking to produce customized apparel. Unlike traditional methods like screen printing, DTF allows for complex designs with graduated colors and fine details, catering to the needs of contemporary fashion and promotional items. As a result, it enables brands to offer unique, personalized products that stand out in the competitive market of custom apparel.

The Rise of DTF Transfers in Custom Apparel

DTF transfers have quickly become a preferred choice for custom apparel due to their exceptional versatility. Whether it’s for creating custom t-shirts, hoodies, or even sports uniforms, DTF printing accommodates various fabric types and allows for limitless design possibilities. This flexibility has surged the demand for DTF transfers among small businesses and independent creators who can now offer distinct designs without the limitations posed by other printing techniques.

Moreover, the quality achieved through DTF printing is unmatched. The prints have a soft hand feel and maintain their vibrant colors even after multiple washes, contributing to customer satisfaction. As entrepreneurs and businesses strive to innovate within the apparel market, DTF technology serves as an enabler, encouraging creativity while offering a reliable solution for high-quality production.

The Cost Benefits of DTF Transfers

One of the most compelling advantages of DTF transfers is their cost-effectiveness, particularly for startups and small businesses. Unlike traditional fabric printing methods that often require significant setup costs and large minimum orders, DTF technology reduces these barriers, making it easier for entrepreneurs to enter the market. This affordability extends to the materials as well, as DTF printing utilizes less ink and resources compared to screen printing.

Furthermore, the ability to produce small batches without incurring high costs allows creators to experiment with designs and respond quickly to market trends. As fashion is notoriously fickle, DTF transfers enable businesses to adapt their collections and offer new styles without the risk of overproduction. This makes DTF a strategic choice for those pursuing efficiency and creativity in the competitive landscape of custom apparel.

Sustainable Aspects of DTF Printing

As sustainability becomes an increasingly critical factor in consumer decision-making, DTF printing stands out for its eco-friendly attributes. Utilizing water-based inks and minimizing waste during the printing process, DTF technology aligns with the growing demand for sustainable fashion solutions. This method significantly reduces the environmental impact when compared to conventional fabric printing methods, which often involve harmful chemicals and excess waste.

Furthermore, as consumers become more conscious of their purchasing choices, adopting sustainable practices, including DTF printing, can enhance brand loyalty and appeal to a broader audience. Businesses leveraging this environmentally friendly technology not only contribute to a greener planet but also tap into the lucrative market of eco-conscious consumers eager to support brands committed to sustainability.

DTF Transfer Popularity and Market Growth

The popularity of DTF transfers is rapidly gaining traction in the fabric printing industry, evident from the projected growth rate of over 10% in the coming years. Multiple sectors, including fashion, sportswear, and merchandise, are increasingly adopting DTF printing technology to meet consumer demand for customized and individualistic products. This growth reflects a significant shift in market dynamics, as businesses recognize DTF as a viable alternative to traditional printing methods.

As more players enter the market, innovation in DTF technology is expected to enhance printing capabilities further, offering businesses even more options for customization. The expansion of the DTF printing market highlights the importance of staying ahead in trends and capabilities, allowing companies to leverage DTF’s advantages to meet the evolving needs of customers looking for unique, high-quality apparel.

User-Friendly Nature of DTF Printing Technology

One of the remarkable features of DTF printing is its user-friendly interface, which simplifies the printing process for both hobbyists and professionals alike. Recent advancements in technology have made DTF printers more accessible, allowing individuals without extensive technical knowledge to easily produce high-quality prints. This ease of use encourages wider adoption, allowing more creators to engage in the field of custom apparel.

In addition to user-friendly designs, there are numerous educational resources available to help newcomers understand DTF printing better. As more tutorials and guides flood the market, aspiring printers can confidently explore the capabilities of DTF technology, paving the way for increased participation in the fabric printing space. This accessibility is a critical factor behind the rising popularity of DTF transfers and represents a significant leap forward in democratizing fabric printing.

Frequently Asked Questions

What are DTF transfers and how do they work in fabric printing?

DTF transfers, or Direct-to-Film transfers, are a fabric printing method where designs are printed onto a special film that can be applied to various fabrics using heat and pressure. This innovative process allows for vibrant colors and intricate designs, making it ideal for custom apparel and diverse materials.

Why are DTF transfers becoming popular in the custom apparel market?

DTF transfers are gaining popularity in the custom apparel market due to their versatility and ability to produce high-quality images on multiple fabric types. This technology allows businesses to create detailed and colorful designs at a lower cost, appealing to startups and small brands looking to innovate.

How do DTF transfers contribute to sustainable fashion practices?

DTF transfers promote sustainable fashion by utilizing water-based inks and producing less waste compared to traditional printing methods like screen printing. This eco-friendly aspect aligns with consumer demands for environmentally conscious products, making DTF an excellent choice for sustainable fabric printing.

What are the cost benefits of using DTF printing technology?

The cost benefits of DTF printing technology include lower initial setup costs and the ability to print small runs of garments without significant financial risk. This affordability allows businesses, especially startups, to experiment with custom designs without the high investment associated with traditional fabric printing methods.

What factors contribute to the expected growth of the DTF printing market?

The DTF printing market is projected to grow significantly, driven by increasing adoption in sectors like fashion and custom merchandise. Factors contributing to this growth include the demand for customizable products, advancements in DTF technology, and the ongoing shift towards sustainable fashion solutions.

Is DTF printing technology user-friendly for beginners?

Yes, DTF printing technology is designed to be user-friendly, with simplified operations and interfaces that make it accessible for beginners and hobbyists. This accessibility allows more individuals to enter the world of fabric printing, increasing the popularity of DTF transfers in the market.

| Key Point | Description |

|---|---|

| Understanding DTF Transfers | A printing process where designs are transferred from a film to fabric using heat and pressure, offering versatility and quality. |

| Versatility and Quality | Compatible with various materials and allowing high-resolution prints, making it ideal for custom apparel and promotional items. |

| Cost-Effectiveness | Lower initial investment compared to traditional methods, beneficial for startups and small businesses. |

| Sustainability | Uses water-based inks and produces less waste, aligning with eco-friendly practices in fashion. |

| Market Growth | Predicted to grow over 10% CAGR, driven by demand in fashion, sportswear, and custom merchandise. |

| User-Friendly Technology | Accessible DTF printers with simplified operations attract both hobbyists and professionals. |

Summary

DTF transfers are revolutionizing the fabric printing industry by offering a blend of innovation, quality, and sustainability. As a method that allows for intricate designs and vivid colors on various materials, DTF transfers present an ideal solution for businesses and consumers alike. The growth of this technology is driven by its cost-effectiveness and ecological advantages, making it an attractive choice for personalized and custom printing. With rising consumer interest in sustainable fashion, DTF transfers are well positioned to meet today’s market demands, indicating a bright future for this printing technique.