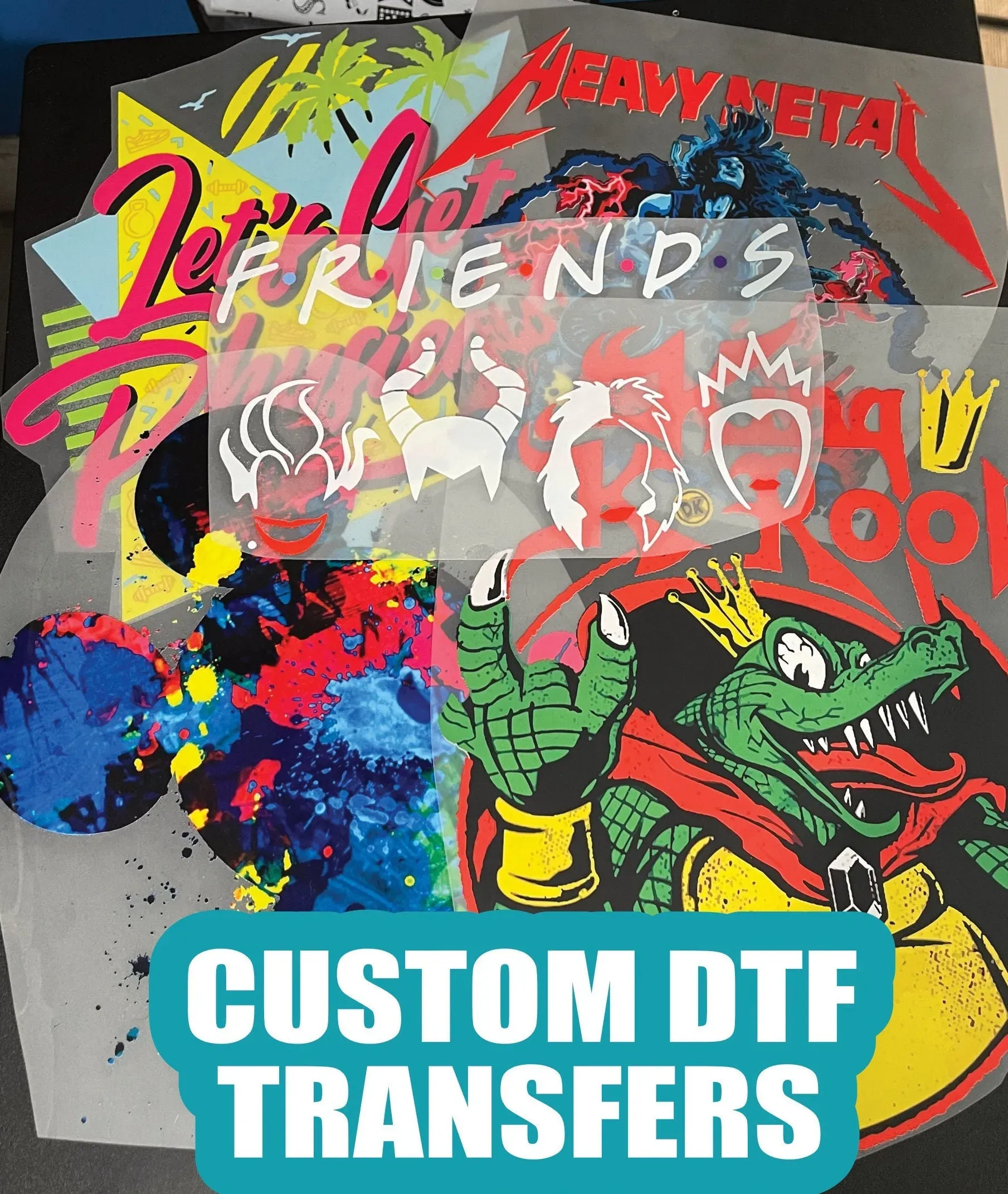

DTF transfers, or Direct-to-Film transfers, represent a remarkable leap in the world of custom apparel and printing technology. This innovative method allows businesses and creators to produce high-quality designs on a variety of fabrics with unparalleled ease and precision. As the demand for sustainable printing solutions grows, DTF technology stands out for its environmentally friendly processes and vibrant output. No longer confined by the limitations of traditional printing methods, companies can now offer diverse product lines that cater to individual preferences and trends. With DTF transfers at the forefront, the future of garment decoration shines brightly, ushering in a new era where creativity knows no bounds.

Alternative terms for DTF transfers include Direct-to-Film printing, a modern technique that is redefining the landscape of custom textile decoration. This innovative printing method enables the application of stunning graphics across an array of materials such as cotton, polyester, and blends. As a versatile solution, DTF is quickly becoming the go-to choice for businesses seeking to enhance their offerings in the world of personalized apparel. Furthermore, this technology aligns with growing trends in sustainable printing, as it often employs eco-friendly inks that minimize environmental impact. With its rapid adoption and impressive capabilities, DTF printing is undeniably a pivotal force driving the future of custom printing.

The Game-Changing Benefits of DTF Transfers

DTF transfers are revolutionizing the printing landscape with their unmatched versatility. Unlike traditional methods, such as Direct-to-Garment (DTG) printing or screen printing, DTF printing can seamlessly adapt to a wide variety of materials. Whether it’s cotton, polyester, or blends, DTF technology ensures that intricate designs can be printed with vibrant colors while maintaining their durability. This adaptability allows businesses more freedom in their product offerings, catering to diverse consumer preferences without compromising on quality.

Moreover, the benefits of DTF printing extend beyond just fabric compatibility. With its straightforward process that relies on a printer and a heat press, DTF transfers simplify production setups for businesses. This element is particularly advantageous for small enterprises looking to enter the custom apparel market. By eliminating complex procedures and reducing equipment costs associated with other methods, DTF technology opens the door for innovation and creativity among budding entrepreneurs.

Sustainability in Printing: The Eco-Friendly Appeal of DTF

Sustainability is becoming a cornerstone in the decision-making processes of businesses today. DTF transfers represent a step toward more eco-friendly practices in the printing industry. The inks used in DTF printing are often water-based and less harmful than those traditionally used, making them a safer option for both the environment and the workers involved in the manufacturing process. This alignment with green principles is increasingly attracting companies that prioritize sustainability as part of their core values.

Additionally, the efficiency of DTF transfers contributes to reducing waste during production. With DTF printing, the process is designed to minimize material wastage, thus promoting a more sustainable approach to custom apparel manufacturing. As consumers become more conscientious of the environmental impact of their purchases, businesses utilizing DTF technology can effectively market their offerings as environmentally friendly, gaining a competitive edge in a crowded marketplace.

DTF Transfers vs Traditional Methods: A Comparative Analysis

When comparing DTF transfers to traditional printing methods, the advantages become clear. Traditional techniques like screen printing often involve extensive setup times and are limited in fabric options, making them less flexible for businesses aiming to meet today’s fast-paced market demands. In contrast, DTF printing allows for quick-design iterations and can accommodate a wider variety of fabric types, from cotton to polyester blends. This level of adaptability is vital for businesses focused on customization and unique offerings.

Furthermore, DTF transfers significantly reduce the need for large minimum orders that traditional printing methods may impose. This flexibility not only allows businesses to cater to smaller markets and niche products but also helps in effectively managing inventory. By enabling print-on-demand capabilities, DTF technology positions itself as a truly modern solution tailored for the evolving needs of custom apparel brands.

Quick Turnaround Times with DTF Technology

In today’s e-commerce age, customer expectations revolve around speed and personalization. DTF transfers excel in providing rapid turnaround times, ensuring that business owners can fulfill orders quickly without the delays often associated with traditional printing methods. This efficiency is crucial for maintaining customer satisfaction and staying competitive in a landscape where consumers demand instant gratification.

Additionally, the effectiveness of DTF printing eliminates the need for extensive pre-production considerations, as designs can be processed and applied quickly. With DTF technology, businesses can respond promptly to shifts in consumer demand, thereby increasing their potential revenue streams through swift execution of custom orders. This ability to be agile and responsive is a game-changer in the fast-paced world of custom apparel.

The Role of Technology in Advancing DTF Printing

Technological advancements play a pivotal role in enhancing the capabilities of DTF transfers. Modern developments in printer technology are leading to better resolution and faster printing speeds, allowing for even finer details in designs. Furthermore, innovations in ink formulations contribute to stronger adhesion to fabrics, resulting in prints that not only look spectacular but also stand the test of time through frequent washes and wear.

As manufacturers continue to introduce cutting-edge solutions to improve DTF printing processes, the quality of output keeps evolving. Businesses that embrace these advancements can consistently deliver high-quality products that appeal to discerning consumers, thus solidifying their position in the market. By staying current with technological trends, businesses can leverage DTF technology to boost their production efficiency while enhancing product offerings.

Market Trends: Personalization and Consumer Demand

The current market trends highlight a growing consumer desire for personalized products. DTF printing is ideally positioned to cater to this demand, enabling businesses to offer customized apparel that appeals directly to individual tastes. With DTF technology, brands can easily create unique designs for their customers, ranging from one-off pieces to limited-edition collections, thereby fostering deeper connections with their consumer base.

Furthermore, as brands adopt DTF transfers, they not only respond to consumer desires but also distinguish themselves in a crowded market. The ability to offer personalized options can enhance brand loyalty, as customers value unique items that reflect their personal style. This trend not only fuels sales but also provides an opportunity for brands to build a strong identity around customization, ensuring longevity in the competitive landscape of custom apparel.

Frequently Asked Questions

What are DTF transfers and how do they work in custom apparel production?

DTF transfers, or Direct-to-Film transfers, are a modern printing technology used in custom apparel production. This process involves printing designs onto a special film using high-quality inks. The printed film is then transferred onto the fabric through a heat press, allowing vibrant colors and intricate details to be applied to various materials such as cotton, polyester, and blends.

What are the key advantages of using DTF technology over traditional printing methods?

DTF technology offers several advantages, including versatility, ease of use, and cost-effectiveness. Unlike traditional printing methods, DTF transfers can be applied to a wider range of fabrics and produce high-quality prints with better durability. Additionally, the setup is user-friendly and requires less initial investment, making it suitable for small businesses and startups.

Is DTF printing a sustainable option for businesses focused on eco-friendly practices?

Yes, DTF printing is considered a sustainable option as it utilizes water-based inks that are less harmful to the environment than traditional solvent-based inks. This eco-friendly approach helps businesses meet consumer demand for sustainable printing practices while reducing their carbon footprint in the custom apparel sector.

How does DTF printing support quick turnaround times for custom orders?

DTF printing technology enables rapid turnaround times by allowing businesses to quickly produce and apply designs onto garments. The efficiency of DTF transfers means that orders can be fulfilled faster than traditional printing options, catering to the growing consumer demand for personalized and custom apparel.

What types of fabrics can be used with DTF transfers?

DTF transfers are highly versatile and can be applied to a wide variety of fabrics, including cotton, polyester, and blended materials. This versatility allows businesses to create custom apparel that meets diverse consumer preferences and expands their product offerings.

How do advancements in DTF technology improve print quality and efficiency?

Recent advancements in DTF technology have led to improved printer resolutions and faster printing speeds, enhancing overall print quality. Manufacturers are also innovating with new ink formulations that create stronger bonds with fabrics, resulting in long-lasting prints that withstand wear and washing, making DTF technology an efficient choice for custom apparel production.

| Key Points | Details |

|---|---|

| Introduction | Direct-to-Film (DTF) transfers are revolutionizing the printing industry with vibrant colors and versatile fabric compatibility. |

| Rising Popularity | DTF transfers are favored due to their ability to cater to diverse fabric types and meet consumer demands for high-quality products. |

| Advantages | 1. Versatility: Works on various fabrics. 2. Ease of Use: Requires minimal equipment. 3. Cost-Effectiveness: Lower startup costs than DTG. 4. Rapid Turnaround: Meets high consumer demand quickly. |

| Technology Advancements | Improvements in print quality, speed, and durable inks are boosting DTF effectiveness and appeal. |

| Market Trends | Growing demand for personalized apparel and eco-friendly printing practices is pushing DTF to the forefront. |

| Conclusion | DTF transfers are shaping the future of garment decoration, with advantages that position them as a durable and innovative option. |

Summary

DTF transfers are rapidly becoming the go-to method in the printing industry, transforming how customization is approached in fashion and merchandise. With its versatility to print on various fabrics, lower costs compared to traditional methods, and quick application process, DTF technology caters to modern consumer demands for personalized products. Furthermore, advancements in technology enhance the capabilities of DTF printing, ensuring high-quality and environmentally sustainable outcomes. As businesses adapt to these innovations, the future looks bright for DTF transfers in leading the way for garment decoration.