In the ever-evolving landscape of modern printing techniques, **DTF transfers** (Direct to Film) have emerged as a game-changer in the world of custom apparel printing. This innovative DTF printing technology is rapidly gaining popularity for its ability to deliver superior, high-quality prints that cater to a wide spectrum of creative needs. From fashion designers looking to create vibrant, eye-catching garments to businesses aiming for intricate branded merchandise, the benefits of DTF transfers are nothing short of transformative. Offering durable transfer printing that withstands the rigors of everyday wear and tear, DTF technology showcases its versatility across various materials, making it an essential tool for any printing enthusiast. In this comprehensive guide, we’ll delve into the myriad advantages of DTF transfers and explore why they are revolutionizing the printing industry.

When discussing the innovative approach to printing known as Direct to Film (DTF) transfers, it’s essential to understand the terminology that surrounds this technology. By utilizing advanced printing methods, proponents of this technique appreciate its adaptability, whether referred to as DTF printing or custom heat transfer solutions. This modern approach allows for a remarkable level of precision and durability in creating personalized apparel and promotional items. As industries shift toward digital printing methods, terms like durable transfer printing and high-resolution graphics capture the essence of what DTF offers, enticing businesses to explore this robust technology. Ultimately, the flexibility and quality associated with DTF transfers make them a notable contender in the realm of contemporary printing techniques.

Understanding the Mechanics of DTF Transfers

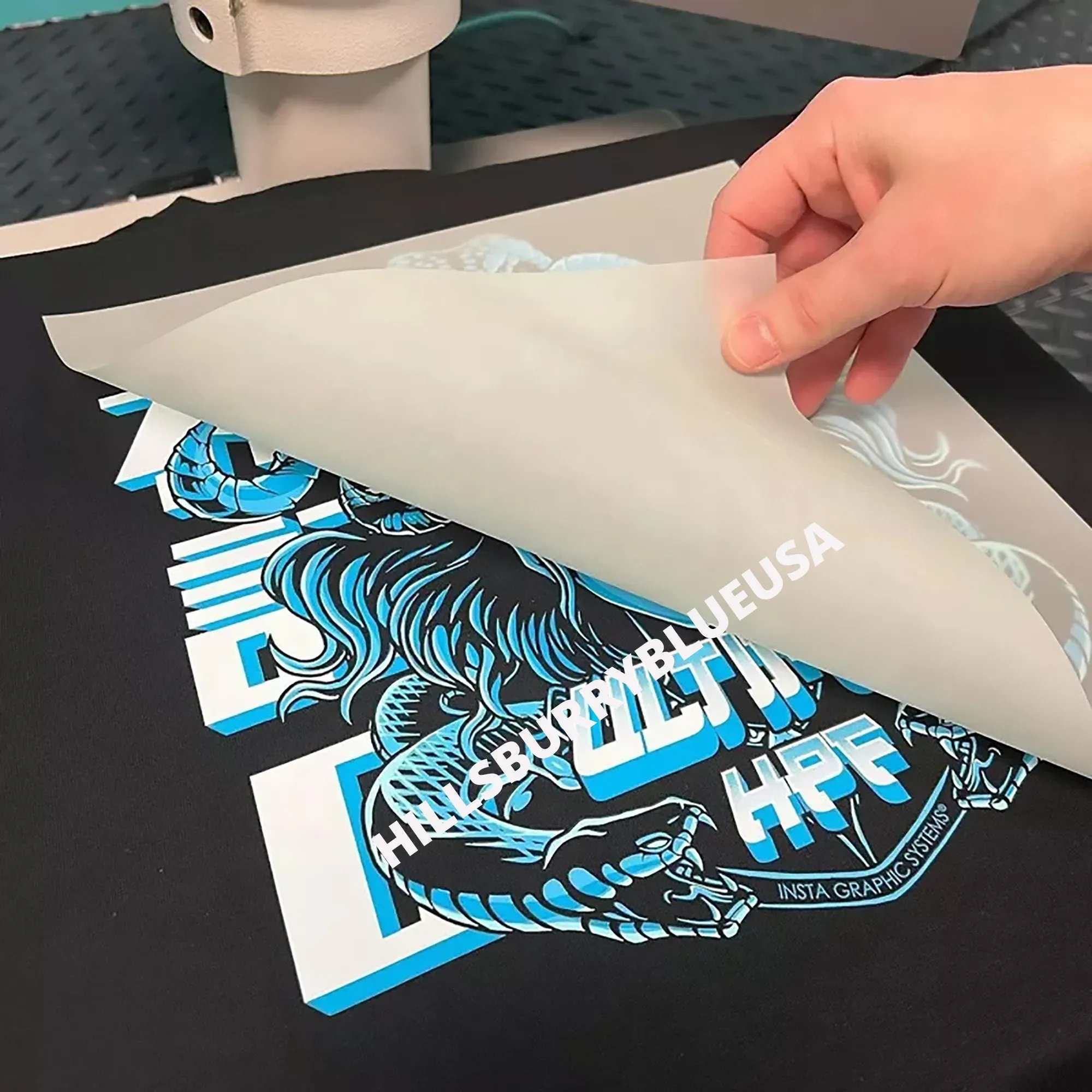

DTF transfers operate on a unique process that sets them apart from traditional printing methods. Initially, designs are printed onto a special film with water-based inks that are praised for their vibrancy and eco-friendliness. This film is then coated with a powder adhesive, which is melted onto the printed side to ensure an optimal bond when heat is applied. The resulting print is allows for stunning color representation, capturing gradient shifts and intricate details that can often be lost in other methods.

The application of heat and pressure is a pivotal step in the DTF process, enabling the print to fuse seamlessly onto various fabrics. This crucial mechanism ensures that the designs remain intact and do not peel or crack easily over time, adding to the durability and longevity of the product. As businesses look for ways to provide high-quality custom apparel, understanding the mechanics behind DTF transfers becomes vital to maximizing their effectiveness.

The Surging Popularity of DTF Printing Technology

In recent years, DTF printing technology has gained momentum as one of the most sought-after methods for custom apparel printing. Its ability to produce high-quality prints at a rapid pace has made it ideal for businesses looking to adapt to the increasing consumer demand for personalization. E-commerce platforms, in particular, are leveraging DTF technology to cater to unique design requests, enabling customers to create one-of-a-kind items like bespoke clothing or tailored merchandise.

The surge in popularity can also be attributed to advancements in technology, which have improved the printing process, resulting in brighter colors and more precise details. Additionally, the affordability of DTF printing allows smaller businesses to enter the market without the hefty investments typically associated with traditional screen printing. As a result, many entrepreneurs are embracing DTF transfers as their go-to solution for high-quality, customizable products.

Exploring the Versatility of DTF Transfers Across Materials

DTF transfers are heralded for their remarkable versatility, which allows them to be applied to an array of materials beyond just cotton garments. This adaptability expands possibilities for product ranges, such as printed tote bags, caps, or even home decor items. By tapping into this versatility, businesses can reach a broader customer base and offer an enhanced selection of customized products that cater to different tastes and preferences.

From polyester sportswear that requires high elasticity to blends that prioritize comfort, DTF prints remain effective and visually striking no matter the material. The ability to print on both light and dark fabrics without sacrificing quality opens doors for creatives and businesses alike to produce captivating items that stand out in a competitive market. The diverse capabilities of DTF technology make it a compelling choice for anyone looking to enrich their product offerings.

Enhancing Durability Through DTF Printing

One of the standout features of DTF transfers is their unmatched durability compared to traditional printing methods. These prints are engineered to withstand the rigors of everyday wear, comprising a strong bond with the fabric that resists cracking and fading, even after multiple wash cycles. This durability is particularly critical for businesses producing promotional items or custom work clothing that need to maintain their appearance over time.

Moreover, the resistance to washing and fading ensures that products created with DTF technology look fresh and new long after purchase. This element of resilience not only enhances customer satisfaction but also adds value to the products, as consumers are less likely to seek replacements. Understanding this aspect of DTF transfers can empower businesses to market their products more effectively, highlighting their longevity as a key selling point.

Cost-Effectiveness of DTF Transfers for Small Businesses

One of the most appealing advantages of DTF transfers is their cost-effectiveness, particularly for small batch orders or custom designs. Unlike traditional screen printing—which often involves significant setup costs and is economically feasible primarily for large volumes—DTF allows for a more approachable entry point for businesses looking to produce limited runs. This flexibility enables entrepreneurs to maintain low overheads while still delivering quality products to customers.

Additionally, the lower initial investment required for DTF equipment compared to screen printing setups means that startups and small businesses can allocate their budgets toward other vital areas, such as marketing and branding. As a result, DTF transfers not only reduce financial barriers but also democratize the custom apparel printing landscape, enabling more creative individuals and small ventures to thrive.

Sustainability Benefits of DTF Printing Technology

In an era where environmental considerations are increasingly paramount, DTF printing technology stands out as a more sustainable option compared to traditional methods. Utilization of water-based inks significantly reduces harmful chemical emissions, ensuring a safer working environment and lower environmental impact. This eco-friendly approach resonates especially well with consumers who prioritize sustainability when making purchasing decisions.

Moreover, because DTF printing often results in less material waste due to its efficient production processes, it presents an appealing alternative for businesses striving to be more environmentally responsible. As sustainability becomes a crucial factor for consumers, adopting DTF technology can help companies not only improve their production practices but also enhance their brand reputation by aligning with eco-conscious values.

Frequently Asked Questions

What are the benefits of DTF transfers in custom apparel printing?

DTF transfers offer several benefits in custom apparel printing, including high-quality prints with vibrant colors and sharp detail, versatility to print on various fabrics, and a durable finish that withstands washing. Additionally, DTF technology is cost-effective for small runs and simplifies the printing process, making it ideal for businesses looking to meet customer demands for personalized products.

How does DTF printing technology ensure high-quality prints?

DTF printing technology guarantees high-quality prints by using advanced printing techniques that allow for a wider color gamut and precision detail. This results in designs that are vibrant, intricate, and true to the original artwork, making DTF transfers a favored choice for businesses aiming for eye-catching and professional apparel.

Are DTF transfers versatile for different types of fabrics?

Yes, DTF transfers are highly versatile and can be applied to various materials, including cotton, polyester, and fabric blends. This adaptability allows businesses to expand their product offerings beyond clothing to include items like bags and home textiles, appealing to a broader audience.

What makes DTF transfers more durable than other printing methods?

DTF transfers are known for their durability due to the advanced inks and transfer process used, which ensures that prints maintain their vibrancy and do not fade significantly even after multiple washes. This high level of wash resistance makes DTF a reliable choice for promotional products and custom garments that need to endure wear and tear.

How are DTF transfers cost-effective for small runs compared to traditional printing?

DTF transfers are cost-effective for small runs because they require lower initial investments and minimal setup compared to traditional methods like screen printing. This efficiency allows businesses to fulfill custom orders quickly without incurring high overhead costs, making it ideal for on-demand printing.

What environmental benefits do DTF transfers offer?

DTF transfers provide environmental benefits through the use of water-based inks, which reduce chemical waste, and a more efficient production process that minimizes energy consumption and waste. These eco-friendly practices position DTF printing as a sustainable option in the printing industry.

| Key Points | Details |

|---|---|

| High-Quality Prints | – Vibrant colors and sharp details ideal for complex designs. |

| Versatility Across Materials | – Can print on cotton, polyester, and blends, suitable for various products. |

| Durability That Lasts | – Wash-resistant and fade-resistant, perfect for custom garments and promotional items. |

| Cost-Effectiveness for Small Runs | – Lower setup costs compared to traditional screen printing, ideal for small orders. |

| Ease of Use | – Simplified production process allowing for quick turnaround and custom orders. |

| Environmental Considerations | – Utilizes water-based inks and reduces waste, making it eco-friendly. |

| Current Trends | – Increasing customization demand, technological innovations, and e-commerce integration. |

Summary

DTF transfers are revolutionizing the printing industry by offering unparalleled benefits that cater to the modern consumer’s demands. These transfers deliver high-quality prints that boast vibrant colors and intricate details, ensuring that every design stands out. Their versatility allows for applications across a range of materials, enhancing the potential for product expansion beyond traditional apparel. DTF transfers are also highly durable, enduring multiple washes without fading, making them perfect for custom garments and promotional items. Economically, they support small run productions with lower setup costs compared to traditional methods, while also providing an easy-to-use process that enables quick turnaround times. Moreover, DTF technology is more sustainable, utilizing water-based inks and minimizing waste, which aligns with the growing focus on environmental responsibility. As trends continue to favor customization and quality, embracing DTF transfers could elevate businesses in the competitive printing landscape.