DTF transfers are transforming the landscape of custom apparel printing, bringing innovative solutions to those seeking high-quality and personalized designs. The Direct to Film (DTF) printing technology stands out as a key advancement in the realm of printing innovations, allowing intricate designs to be printed on a special film before being transferred onto garments. This method not only enhances the vibrancy of colors but also provides a level of versatility that traditional printing techniques, like screen printing, often struggle to match. With the increasing demand for unique apparel, DTF heat transfers have become a go-to option for businesses aiming to elevate their product offerings. As we delve deeper into the capabilities of DTF technology, we will uncover how this approach is shaping the future of textile printing, making it an essential player in the evolving world of fashion.

In the realm of modern printing, Direct to Film technology, commonly referred to as DTF, is gaining significant traction among custom apparel producers. This innovative method allows designs to be seamlessly transferred onto a variety of fabrics, catering to the growing consumer preference for uniqueness and quality in their clothing choices. DTF heat transfers are particularly notable for their ability to produce stunning graphics with exceptional durability, setting a new standard in the industry. As printing innovations continue to emerge, the importance of embracing DTF printing cannot be overstated, especially for businesses looking to remain competitive in the dynamic landscape of garment customization. By exploring alternative fabrication methods, companies can meet consumer demands while simultaneously maximizing efficiency in production.

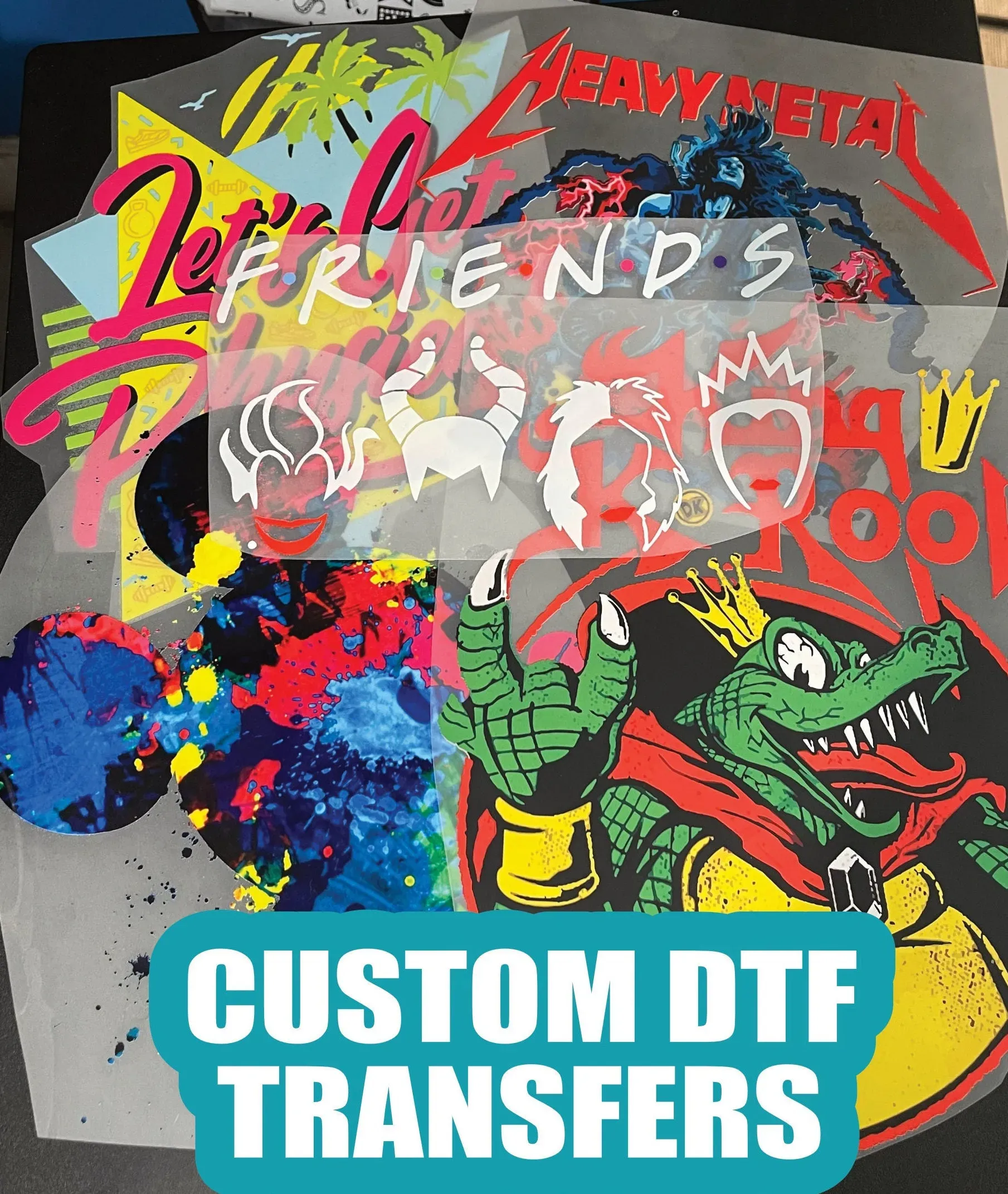

Understanding DTF Transfers and Their Impact on Apparel Printing

DTF Transfers, or Direct to Film transfers, represent a significant leap forward in the world of textile printing. This innovative method employs a specialized film to capture vibrant designs, which can then be seamlessly heat transferred onto various fabrics. Unlike traditional methods, which often involve tedious setup processes, DTF transfers allow for quicker production times, catering to the fast-paced demands of today’s custom apparel market. Their versatility enables designers to achieve intricate and colorful patterns that embody both creativity and high-quality standards.

The impact of DTF transfers on the apparel industry is profound. As more businesses adopt this technology, they find themselves capable of producing unique, high-resolution designs on-demand, which leads to reduced waste and enhanced customer satisfaction. With the increasing consumer desire for personalized clothing options, the DTF printing process addresses these needs efficiently. Consequently, DTF transfers not only elevate the standard for what consumers expect from custom apparel but also encourage sustainable practices in production.

The Latest Innovations in DTF Technology

In recent years, advancements in DTF technology have accelerated, pushing the boundaries of what’s possible in the textile printing industry. For instance, companies have introduced new ink formulations specifically designed to enhance print durability and vibrancy. Innovations in application processes, such as quicker heat transfer times and improved adhesive properties, ensure that prints withstand the test of time, even after multiple washes. This leap in quality aligns perfectly with consumer expectations for long-lasting and eye-catching apparel.

Another significant innovation is the development of user-friendly software that supports DTF printing processes. This includes enhanced graphic design tools that help businesses create eye-catching designs tailored for various fabric types. By streamlining the design-to-print workflow, these technological advancements empower small businesses and entrepreneurs to enter the market without needing extensive technical expertise, making DTF technology not only accessible but also highly efficient.

Leveraging DTF Transfers for Custom Apparel Success

For businesses aiming to stand out in the competitive custom apparel market, leveraging DTF transfers can be a game-changing decision. DTF technology allows for intricate designs that can resonate with target audiences, potentially elevating brand identity. The ability to personalize items efficiently means that businesses can cater to niche markets with specialized offerings, driving consumer engagement and loyalty. Moreover, DTF printing reduces the cost barriers often associated with traditional methods as there is no need for large minimum orders, making it accessible for small businesses.

Furthermore, utilizing DTF transfers enables companies to experiment with various materials and textures, broadening their product offerings. As fashion trends evolve, businesses can quickly adapt their design approaches while maintaining high-quality output. This flexibility provides a significant advantage over competitors reliant on outdated printing methods, ensuring that they can keep pace with the demands of a rapidly changing market landscape.

The Benefits of DTF Heat Transfers in Printing

DTF heat transfers bring an array of benefits that make them an attractive choice for businesses engaged in custom printing. First and foremost, the ease of application allows for swift production times, meaning companies can fulfill orders faster than ever before. Coupled with the high-resolution output, DTF heat transfers enable businesses to produce stunning designs that captivate consumers from the first glance.

Moreover, DTF heat transfers possess exceptional durability, resisting fading and cracking over time, which is crucial for maintaining product quality. This resilience not only enhances consumer trust but also contributes to a sustainable business model by reducing the need for reprints. As organizations strive to meet consumer demands for quality and sustainability, DTF heat transfers emerge as a viable solution that meets both business and environmental goals.

Global Expansion of DTF Printing Capabilities

The global expansion of DTF printing capabilities is reshaping the customs apparel landscape. As more manufacturers invest in DTF technology, businesses around the world gain access to affordable, high-quality printing solutions. Notably, companies like AM.CO.ZA are pioneering efforts in regions such as South Africa, where initiatives aim to support local print-on-demand markets. This expansion democratizes access to cutting-edge printing technology, enabling aspiring entrepreneurs in diverse markets to explore new business opportunities.

Furthermore, the global reach of DTF printing technology fosters collaboration and knowledge sharing among industry players. As businesses connect across borders, they exchange best practices, design innovations, and technical know-how, driving further advancements in the field. This sense of community is instrumental in establishing standards for DTF printing quality and performance, which ultimately benefits consumers by providing them with higher-quality custom apparel options.

The Future of Custom Apparel and DTF Printing

Looking to the future, the intersection of DTF printing and the custom apparel market signals a promising trajectory for both businesses and consumers. With projections indicating substantial growth in demand for personalized clothing, companies equipped with innovative DTF technology will likely flourish in this evolving landscape. This growth is driven by an increasing consumer insistence on unique designs that reflect individual personalities, making DTF printing an essential method for manufacturers aiming to meet these desires.

Additionally, as the technology behind DTF printing continues to advance—focusing on improved print speeds, quality, and cost-efficiency—more businesses will integrate these methods into their production workflows. This shift not only enhances the overall capabilities of custom apparel companies but also encourages sustainable practices that appeal to today’s eco-conscious consumers. As the market matures, businesses that embrace DTF transfers stand to redefine the apparel industry, setting new standards for quality, sustainability, and creativity in custom printing.

Frequently Asked Questions

What are DTF Transfers in textile printing?

DTF transfers, or Direct to Film transfers, are a revolutionary method in textile printing where designs are printed onto a special film and then transferred onto various fabrics. This technique allows for vibrant colors and intricate designs, making it particularly popular in custom apparel printing.

How does DTF technology compare to traditional printing methods?

DTF technology offers significant advantages over traditional methods such as screen printing and heat transfer. It simplifies the printing process, requires no setup for each design, and allows for quick production times while maintaining high-quality results, making it ideal for custom apparel applications.

What innovations are driving the DTF heat transfers market?

Recent innovations in DTF heat transfers, like new products from companies such as Insta Graphic Systems, focus on enhancing print quality, durability, and vibrant colors. These advancements are setting new industry benchmarks and enhancing the appeal of DTF technology for custom printing businesses.

How can businesses benefit from using DTF transfers for custom apparel?

Businesses can leverage DTF transfers to create high-quality, bespoke designs on-demand without the need for large inventory. This method not only reduces waste but also offers quick turnaround times, increasing customer satisfaction in the competitive custom apparel market.

What future trends can we expect for DTF printing technologies?

The future of DTF printing technologies is promising, with anticipated advancements focusing on speed, efficiency, and print quality. As consumer demand for unique custom apparel grows, DTF transfers are set to become increasingly integral in the apparel printing landscape.

Where can I find high-quality DTF transfers and printing equipment?

High-quality DTF transfers and printing equipment can be sourced from specialized suppliers like Sam’s DTF Transfers and AM.CO.ZA, which offer services and products tailored to the needs of the custom apparel market, ensuring businesses have access to dependable printing solutions.

| Key Concept | Description |

|---|---|

| DTF Transfers | Direct to Film (DTF) transfers allow for intricate designs to be printed on a film, which can then be transferred onto fabric, making it ideal for custom apparel. |

| Customization | DTF technology caters to the rising demand for personalized clothing, enabling on-demand printing that minimizes waste. |

| Industry Innovations | Key players like Sam’s DTF Transfers and Insta Graphic Systems are enhancing DTF products to improve print quality and efficiency. |

| Market Accessibility | Compact DTF printers are making the technology accessible to small businesses without significant upfront costs. |

| Sustainability | DTF transfers promote sustainable practices by reducing material waste and increasing production efficiency. |

Summary

DTF Transfers are transforming the custom apparel landscape by offering vibrant, high-quality print options that cater to modern consumer demands. The innovative technology enables businesses to create detailed designs on-demand, enhancing personalization and sustainability within the printing industry. With notable advancements from leading companies and the growing accessibility of DTF printing solutions, the future looks bright for businesses that embrace this cutting-edge method. As personalization continues to drive market growth, DTF transfers are poised to redefine how brands approach custom apparel production.