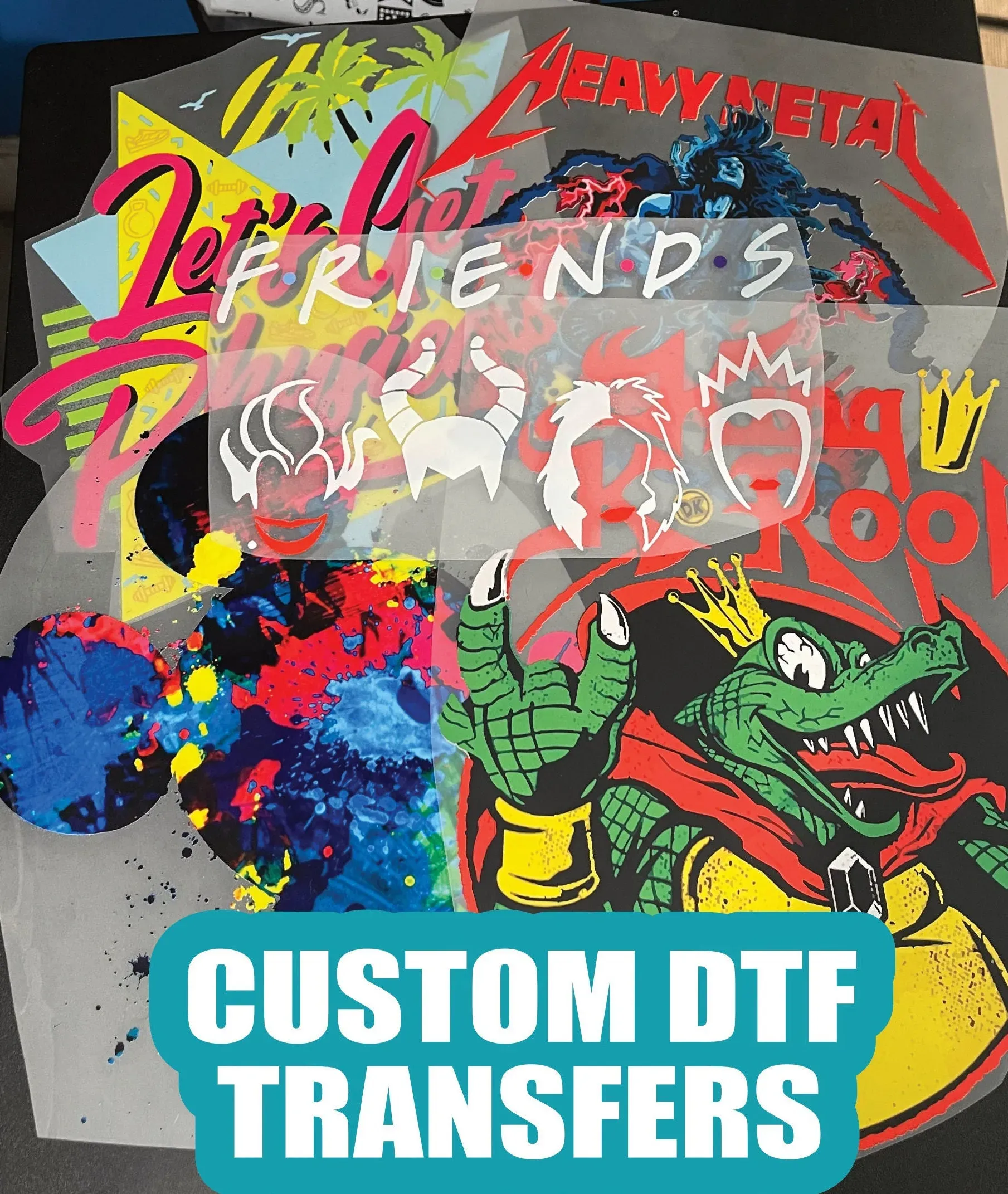

DTF transfers, or Direct-to-Film transfers, have revolutionized the textile printing industry by providing a modern approach to creating vibrant and intricate designs. This innovative printing technique enables users—from small business owners to passionate hobbyists—to seamlessly transfer detailed graphics onto various fabrics with impressive print quality. With the right DTF printing equipment and materials, you can unlock endless creative possibilities and elevate your design game. This guide will introduce you to the DTF transfer process, detailing how to achieve stunning results consistently. By exploring key techniques and tools, you’ll be well on your way to mastering this exciting printing method.

In recent years, the term “Direct-to-Film printing” has gained traction among textile artists and manufacturers alike due to its effectiveness and versatility. Often described as a groundbreaking textile printing technology, this method allows for the detailed transfer of digital designs to fabric surfaces. The DTF printing process entails a series of steps that ensure high-quality output, making it an attractive option for custom apparel creators. Many are eager to learn how to do DTF transfers, understanding that the right equipment and techniques can result in eye-catching products. As this method continues to gain popularity, it opens doors to many opportunities in the realm of custom design.

What is DTF Printing and Its Advantages?

Direct-to-Film (DTF) printing is a revolutionary method in the textile printing industry that allows for high-quality, detailed designs to be transferred onto fabrics. This technique utilizes specialized printers that apply vibrant inks onto a film, which is then transferred onto various materials. The advantages of DTF printing are numerous, including its versatility to print on a wide range of fabrics, from cotton to polyester blends. Additionally, DTF transfers maintain excellent wash durability, ensuring your designs stay vibrant even after multiple washes.

One of the primary benefits of DTF transfers is the quality of the print. DTF prints are known for their sharpness, vibrant colors, and the ability to reproduce intricate details that might be difficult with traditional methods like Direct-to-Garment (DTG) printing. Furthermore, DTF is a cost-effective solution for small production runs, making it ideal for custom apparel businesses or hobbyists looking to create unique pieces without high upfront costs.

Equipment Needed for DTF Transfers

To embark on your DTF printing journey, it’s essential to gather the right equipment and materials. Firstly, a high-quality inkjet printer specifically designed for DTF printing is crucial. This specialized printer ensures that the inks adhere properly to the film, resulting in high-fidelity images. Equally important is the use of high-quality DTF inks, which are specially formulated to offer vibrant colors and excellent durability.

Moreover, DTF transfer films play a vital role in achieving optimal results. These films are designed to work seamlessly with the DTF printing process and must be compatible with your printer. Along with films and inks, powdered adhesives are necessary for proper adhesion of the design to the fabric. Each of these components is tailored to enhance the overall print quality, and investing in quality equipment will significantly improve your final product.

The DTF Transfer Process Explained

The DTF transfer process is a step-by-step procedure that starts with designing your artwork using graphic design software. Once you have your design finalized, you must ensure that your file meets the specifications for DTF printing, typically requiring a high-resolution PNG or TIFF format. Following that, you will print your design onto DTF film, taking care to adjust your printer settings for optimal ink saturation and color profiles.

After printing, the next crucial step is to apply a powdered adhesive onto the wet ink of the film. This application enhances the adhesion properties of the print, ensuring a long-lasting transfer. Once the adhesive is applied, curing it using a heat press solidifies the bond, preparing it for the actual transfer onto your fabric. This methodical approach ensures that each aspect of the DTF transfer process is accounted for, resulting in a stunning final product.

Achieving High Quality in DTF Printing

Achieving high print quality in DTF printing involves several key factors, starting with the choice of materials. The quality of your DTF inks is paramount; investing in premium inks will yield more vibrant and durable results. Additionally, the DTF film you choose must be of the highest quality, as it directly impacts the print’s adhesion and clarity on the fabric.

Another crucial aspect is the printer settings and calibration. It is important to fine-tune the printer settings according to the specific requirements of DTF printing, ensuring that ink saturation and color profiles are correctly set to prevent issues like bleeding or smudging. By paying attention to these details and conducting test prints, you can significantly enhance DTF print quality, leading to a polished and professional finish.

Caring for DTF Transfers

Proper care and maintenance of DTF transfers are essential for ensuring the longevity of your designs. After the transfer is complete, it is advised to let the garment cool down before gently peeling away the DTF film. Following this, garment maintenance plays a critical role; hand washing is often recommended to preserve the integrity of the print. If machine washing is necessary, always turn the garment inside out to protect the design from friction and potential damage.

Additionally, using mild detergents and avoiding high heat settings in the dryer can help maintain the vibrancy and durability of your DTF prints. By adhering to these care guidelines, you can ensure that your custom garments remain looking fresh and intact, showcasing the stunning designs for a long time.

Emerging Trends in DTF Printing

The rapidly evolving landscape of DTF printing is characterized by emerging trends that are reshaping the custom apparel market. Notably, a growing preference for eco-friendly solutions has prompted many manufacturers to innovate by developing sustainable inks and films that align with consumer demands for environmentally responsible practices. This shift not only attracts eco-conscious customers but also sets businesses apart in a competitive market.

Moreover, education is increasingly becoming a vital element in the adoption of DTF printing. Many online platforms are now offering workshops, tutorials, and comprehensive guides that help both beginners and seasoned professionals to refine their skills in DTF printing. This emphasis on education ensures that individuals can stay abreast of the latest developments and best practices in DTF technology, enabling them to produce high-quality and sophisticated designs.

Frequently Asked Questions

What is the DTF transfer process and how does it work?

The DTF transfer process, short for Direct-to-Film printing, involves printing high-quality designs onto special films using DTF inks. The printed film is then coated with a powder adhesive, which strengthens the bond to fabric during the heat transfer process. This technique allows for vibrant designs that adhere well to various fabrics.

What DTF printing equipment do I need to get started?

To begin with DTF transfers, you will require a compatible inkjet printer specifically designed for DTF printing, high-quality DTF inks, DTF transfer films, and powder adhesives. This equipment is essential to ensure print quality and successful transfer results.

How can I achieve high DTF print quality?

Achieving high DTF print quality involves using the right DTF printing equipment, ensuring your artwork meets resolution specifications, and maintaining proper printer settings. Additionally, using quality DTF inks and films, along with correct adhesive application and curing, will enhance the vibrancy and longevity of your prints.

Can I create DTF transfers with any type of fabric?

Yes, DTF transfers can be applied to a variety of fabrics, including cotton, polyester, and blends. However, it’s essential to adjust the heat press application based on the fabric type to ensure optimal transfer results and durability.

How do I properly care for garments with DTF prints?

To maintain the quality of garments with DTF prints, it’s recommended to hand wash them or, if using a machine, turn them inside out before washing. Avoid using bleach or harsh detergents and refrain from ironing directly over the print to extend its lifespan.

What are some common mistakes to avoid when doing DTF transfers?

Common mistakes in the DTF transfer process include using low-quality inks or films, not allowing the printed film to dry completely before applying adhesive, and incorrect heat press settings. It’s crucial to follow each step carefully to ensure vibrant and long-lasting designs.

| Key Points | Details |

|---|---|

| Introduction to DTF Transfers | DTF transfers offer vibrant designs for textile printing, catering to businesses and hobbyists. |

| Understanding DTF Transfers | Involves high-quality designs applied to fabrics using specific printing techniques with high-quality inks and films. |

| Step 1: Equipment Needed | Required tools include a compatible inkjet printer, DTF inks, transfer films, and powder adhesive. |

| Step 2: Print Preparation | Design artwork in high-resolution formats (PNG, TIFF) using software like Adobe Illustrator. |

| Step 3: Printing Your Design | Adjust printer settings accordingly and print on DTF film, avoiding ink issues. |

| Step 4: Applying the Adhesive | Evenly sprinkle powder adhesive on the wet ink, then cure with a heat press. |

| Step 5: The Transfer Process | Position the film on the fabric and apply heat for the required time. |

| Step 6: Post-Transfer Care | Let the garment cool, then peel the film and follow washing instructions. |

| Recent Developments | DTF transfers are growing due to market trends, eco-friendly inks, and educational resources. |

Summary

DTF transfers are revolutionizing the world of textile printing by providing artists and businesses an innovative method to create stunning designs. This guide highlights the essential steps and equipment needed to master DTF transfers, ensuring that you can produce vibrant, durable prints on various fabrics. From gathering the right tools to understanding the printing and transfer processes, this comprehensive overview equips you with the knowledge necessary for success in this thriving field. Emphasizing eco-friendliness and accessibility, DTF transfers present opportunities for creativity and sustainability in the custom apparel market.