The DTF Gangsheet Builder is revolutionizing the landscape of custom garment printing, providing a seamless solution for beginners eager to dive into the world of Direct-to-Film (DTF) printing. By allowing users to create multiple designs on a single sheet, this innovative tool not only enhances productivity but also significantly reduces waste, making the DTF transfer process more efficient than ever. This extensive guide serves as a valuable resource for those new to this technology, detailing how to create gang sheets and optimize printing for vibrant and detailed outcomes. With insights drawn from the latest DTF printing guide, even novices can master the art of gang sheet creation. Get ready to unlock your creativity and elevate your custom apparel projects with the DTF Gangsheet Builder!

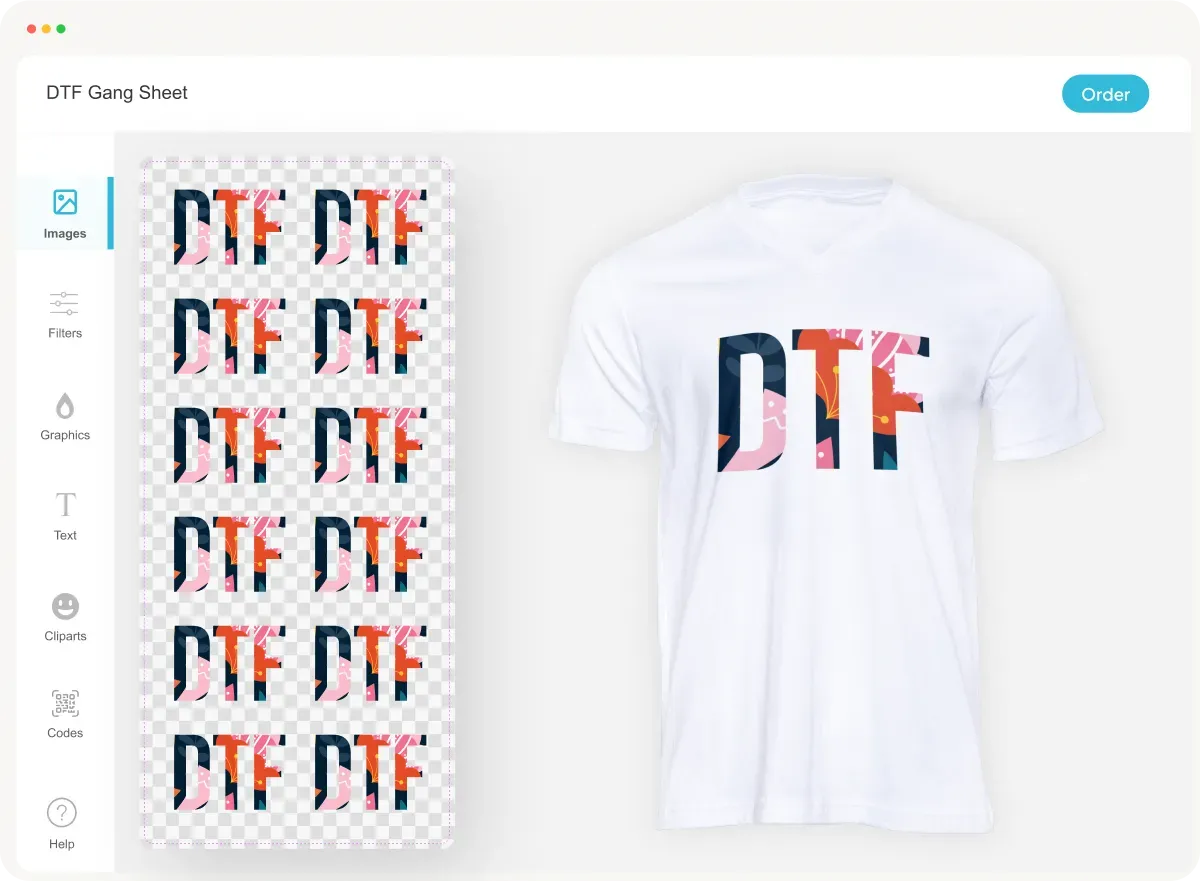

Introducing the DTF Gangsheet Creator, an essential tool for anyone venturing into beginner DTF printing. This innovative solution simplifies the process of producing multiple designs at once, making it an excellent choice for custom textile manufacturing. The concept of gang sheets—where various graphics are combined onto a cost-effective single print—has become indispensable for those looking to maximize efficiency and minimize material waste. By understanding the nuances of the DTF transfer method, you’ll be equipped to create stunning prints that capture the attention of your audience. Whether you’re a hobbyist or an aspiring entrepreneur, utilizing a gangsheet generator can propel your custom garment printing endeavors to new heights.

Understanding the DTF Printing Process

The Direct-to-Film (DTF) printing process offers an innovative approach to custom garment printing, enabling the transfer of vibrant designs onto fabrics with remarkable accuracy. This technique involves a series of steps that begin with creating your designs in specialized design software, followed by printing on PET film using a DTF printer. Understanding the nuances of the DTF transfer process is essential for beginners, as this knowledge helps ensure the integrity of the design and the durability of the print on the fabric.

In addition, mastering the DTF printing methodology removes much of the guesswork that can overwhelm newcomers. By familiarizing yourself with DTF inks, adhesive powder, and the heat pressing technique, you can streamline your workflow and produce high-quality results in your custom garment projects. This foundational understanding serves not only to enhance your skills but also to inspire confidence as you navigate the exciting world of DTF printing.

Creating Custom DTF Gang Sheets Made Easy

Designing a DTF gang sheet can significantly enhance the efficiency of your printing process, allowing multiple designs to be printed simultaneously on a single sheet. To begin, it’s important to learn how to create gang sheets properly, ensuring that the dimensions align with the PET film being used. Utilizing design software, you can arrange your artwork in a manner that maximizes the sheet’s printable area, effectively minimizing waste and saving on material costs.

Furthermore, adhering to best practices during the design phase—such as flipping the images and positioning them correctly—will significantly improve your prints’ quality. Once the designs are organized, the DTF Gangsheet Builder allows you to print with precision, ensuring a seamless production process that can cater to both small and large orders.

Essential Materials for DTF Printing

When embarking on your DTF printing journey, having the right materials at your disposal is crucial. A DTF printer that can handle specialized inks and films is a must-have, along with high-quality DTF inks designed to adhere effectively during the curing process. Additionally, selecting the appropriate PET film tailored for DTF printing enhances the vibrancy and durability of your designs.

Moreover, you’ll need adhesive powder to ensure strong adhesion to the fabric when the transfer is made, and a reliable heat press to apply the necessary heat and pressure. Gathering all these materials beforehand can make your experience smoother and allow you to focus on creating stunning custom garments without interruptions.

Step-by-Step Guide to Mastering DTF Printing

Following a step-by-step guide can be remarkably beneficial for beginners learning the DTF printing process. Begin with gathering all necessary materials as outlined previously, ensuring that everything is within easy reach. Next, create your designs thoughtfully and check dimensions carefully to align with your PET film’s requirements.

Once your designs are set, printing them accurately is vital. Ensure that the DTF printer is correctly configured and that the film is properly loaded. After printing, remember the importance of applying adhesive powder while the ink is still wet to secure a quality transfer. Each step, from printing to heat application, plays a critical role in the outcome of your final product.

Tips for Successful DTF Transfers

For anyone new to DTF printing, practical tips can significantly enhance your success rate. Firstly, practicing on scrap materials before working on actual garments allows for experimentation and technique refinement, preventing costly mistakes on key projects. Understanding the nuances of the inks, films, and printers you’re working with will also aid in preventing common pitfalls.

Furthermore, engaging with online communities dedicated to DTF printing can provide invaluable insights and support. Sharing experiences and troubleshooting within these groups can expand your knowledge and introduce you to new techniques or tools that improve your printing efficiency.

Conclusion: Embracing DTF Printing Innovation

In conclusion, the DTF Gangsheet Builder truly revolutionizes the way aspiring printers approach custom garment production. By efficiently combining multiple designs on a single transfer sheet, creators can embrace the possibilities of DTF printing without the stress of traditional methods. This guide equips beginners with the knowledge needed to start their DTF printing journey confidently.

As you venture into this vibrant world of custom printing, remember that practice and experimentation are essential to becoming proficient. Use the insights from this comprehensive guide along with your creativity to produce stunning prints that stand out in the competitive landscape of custom apparel printing.

Frequently Asked Questions

What is the DTF gangsheet builder?

The DTF Gangsheet Builder is a tool that allows users to create multi-design prints, known as gang sheets, for Direct-to-Film (DTF) printing. It streamlines the process by enabling multiple designs to be printed on a single sheet, saving time and resources while maximizing creativity.

How do I use the DTF Gangsheet Builder for custom garment printing?

Using the DTF Gangsheet Builder for custom garment printing involves first designing your artwork using software such as Adobe Photoshop. Once designs are ready, you load PET film into your DTF printer, print the gang sheet, apply adhesive powder, cure the design with a heat press, and finally transfer it onto your chosen fabric.

What materials do I need for DTF printing with a gangsheet builder?

For DTF printing with a gangsheet builder, you’ll need a DTF printer, DTF inks, compatible PET film, adhesive powder, a heat press machine, and design software to create your artwork. These materials are essential to achieve the best results in your custom printing projects.

Can I learn the DTF printing process as a beginner?

Absolutely! The DTF printing process, including the DTF Gangsheet Builder, is beginner-friendly. Following detailed guides and tips, beginners can quickly grasp the essentials of creating gang sheets, printing, and transferring designs onto garments successfully.

What are the advantages of using the DTF Gangsheet Builder?

The DTF Gangsheet Builder offers several advantages, including reduced printing costs, minimized material waste, and increased efficiency by allowing multiple designs to be printed on a single sheet. This makes it an ideal choice for start-up businesses and hobbyists looking to maximize their custom garment printing capabilities.

What should I consider when creating designs for my DTF gangsheet?

When creating designs for your DTF gangsheet, ensure to check the dimensions of your PET film, use mirrored images for correct transfer, and arrange designs to minimize waste. Additionally, consider the color quality and spacing to achieve the best outcome in your custom garment printing.

| Key Points | Details |

|---|---|

| What is DTF Gangsheet? | A single print combining various designs for fabric transfer, maximizing creativity and efficiency. |

| Core Elements of DTF Printing | Includes DTF printer, inks, PET film, adhesive powder, and heat press. |

| Materials Needed | DTF printer, inks, compatible PET film, powder adhesive, heat press, design software. |

| Printing Process Steps | 1. Create designs using software. 2. Print gang sheet. 3. Apply adhesive. 4. Cure design. 5. Transfer to garment. |

| Tips for Success | Practice on scraps, follow manufacturer guidelines, join online communities for insights. |

Summary

DTF Gangsheet Builder is a revolutionary tool in the printing industry, offering an efficient way to create custom designs for apparel. It allows you to combine multiple designs into one print, significantly reducing waste while producing high-quality prints with vibrant colors. This guide outlines the core components of DTF technology, materials needed, and a clear step-by-step process for beginners. By following these instructions and tips, you can harness the full potential of the DTF Gangsheet Builder, enhancing your creativity and production efficiency in custom apparel printing.