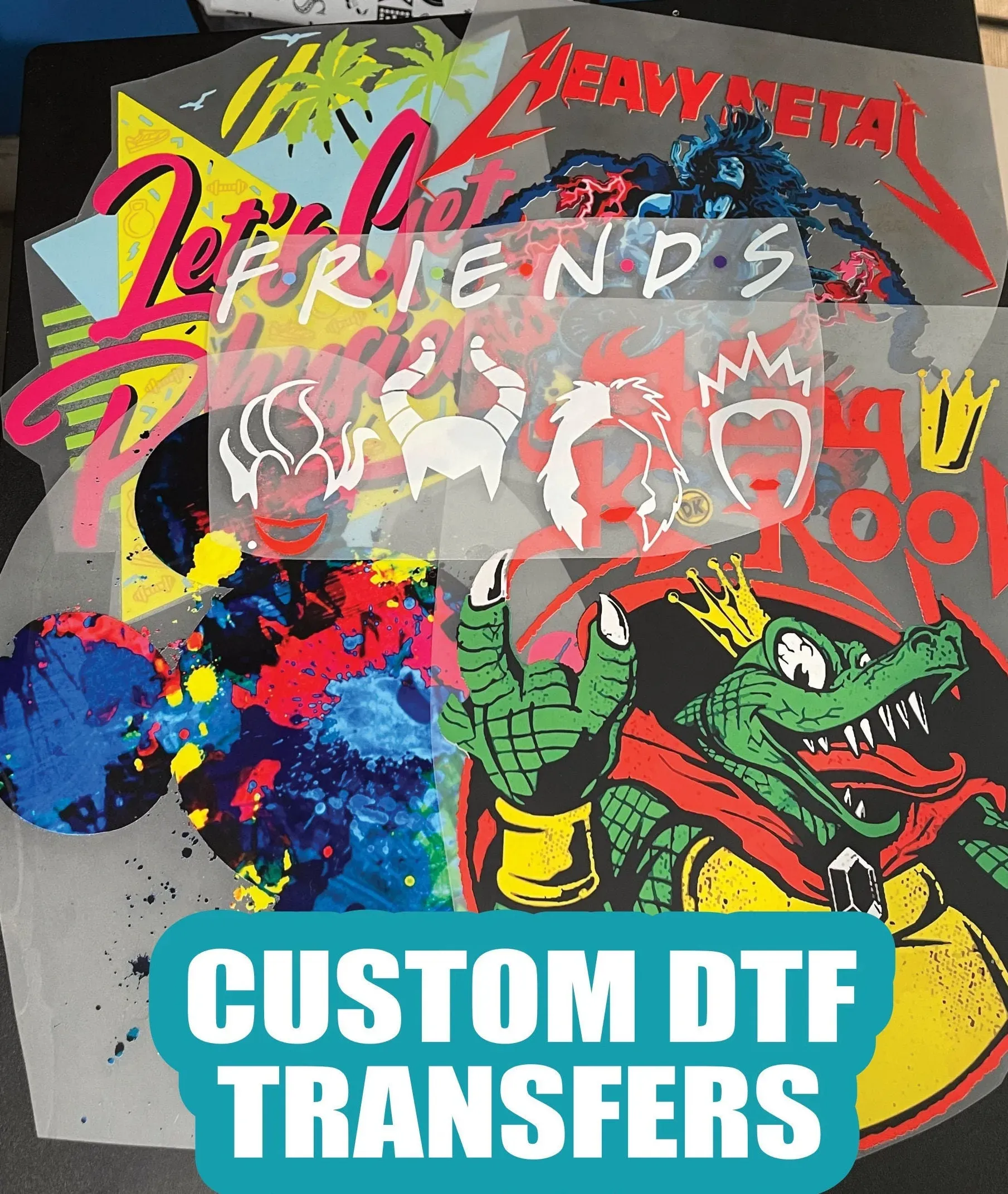

In the world of custom apparel printing, **DTF transfers** (Direct to Film transfers) have revolutionized the way individuals and businesses create eye-catching designs. This remarkable technology provides an innovative approach that allows for vibrant prints to be easily transferred onto various fabric types with unmatched precision. DTF printing has quickly become a favorite among designers due to its versatility and cost-effectiveness, making it an ideal choice for anyone looking to produce high-quality merchandise. In this guide, we will delve into the ins and outs of DTF transfers, including their key advantages and practical applications. Discover how to utilize DTF transfers to elevate your custom apparel game and meet diverse customer demands.

Exploring alternative terms in the realm of textile decoration, Direct to Film printing or DTF technology offers a sophisticated means of applying detailed graphics onto fabrics. This technique transcends traditional printing methods, ensuring that vibrant colors and intricate designs effortlessly adhere to a multitude of materials. Often praised for its flexibility, DTF printing is a boon for small businesses and custom creators who seek to craft unique apparel without the constraints of minimum order quantities. By harnessing the power of film transfers, enthusiasts can experiment with a broader array of fabric types, thereby enhancing their product offerings. As the landscape of **custom apparel printing** continues to evolve, understanding how to leverage DTF transfers will undoubtedly provide an edge in this competitive market.

Understanding the Technology Behind DTF Transfers

DTF transfers leverage advanced printing technologies to deliver striking designs onto a special film. This film serves as a carrier that transports your graphic to the fabric through a heat transfer process. The essence of DTF lies in its ability to bond the printed ink with a wide variety of materials, making it a suitable choice for artists and businesses looking to push the boundaries of custom apparel. By using a blend of eco-friendly inks and durable adhesives, DTF enhances both visual appeal and wearability.

At the heart of DTF technology is the inkjet printer, which ensures precision in printing complex images. It utilizes innovative inks that adhere to both the film and the fabric, resulting in long-lasting prints that maintain their vibrancy even after many washes. The flexibility of this technology means it can accommodate different fabric types, offering broad appeal for various market segments.

The Versatility of DTF Printing for Custom Apparel

One of the standout features of custom apparel printing using DTF transfers is their remarkable versatility. DTF printing can be applied to an extensive range of fabric types, from natural fibers like cotton to synthetic materials such as polyester and intricate blends. This broad application makes it accessible for projects ranging from t-shirts and hoodies to sports gear and bags, providing businesses with the flexibility to meet diverse customer demands.

This versatility translates into an ability for creators to experiment with unique designs and fabrics, empowering them to cater to niche markets or produce one-of-a-kind pieces. By incorporating DTF printing into their offerings, businesses can stand out in a competitive landscape, forging a connection with customers who seek personalized, high-quality apparel.

Incredible Detail and Vibrancy in DTF Prints

DTF printing is known for its superior ability to capture intricate designs and vibrant colors, which sets it apart from traditional printing methods. Artists can take advantage of the technology’s capability to reproduce complex gradients, enabling them to showcase their work in the best possible light. This level of detail is particularly beneficial when striving to evoke emotion or convey a message through visual art.

The rich palette of colors available with DTF printing allows for eye-catching results, ensuring that each design commands attention. Whether it’s a subtle blend or bold contrasts, DTF ensures that your apparel reflects the intended aesthetic, enhancing the overall impression that custom pieces can make.

Exploring the Cost-Effectiveness of DTF Transfers

For small business owners and hobbyists alike, the cost-effectiveness of DTF transfers presents a viable alternative to traditional printing methods. Unlike screen printing, which often requires substantial investments in equipment and materials, DTF allows for a lower barrier to entry. With minimal startup costs, individuals can experiment with different designs without large financial commitments, fostering creativity and innovation.

Moreover, DTF printing eliminates the need for bulk orders, enabling users to fulfill custom orders as they arise. This flexibility caters to the growing demand for personalized apparel and limited-edition items without the pressure of maintaining large inventories. As a result, DTF printing becomes not only a sustainable option but also a lucrative avenue for entrepreneurs aiming to carve their niche in the custom apparel sector.

Maximizing Benefits with DTF Transfers: Usage Guide

Using DTF transfers effectively requires understanding the process from start to finish. First, creators need to ensure that they have the right materials, including film, adhesive powder, and a capable heat press machine. Following the initial design creation using specialized software, the printing onto film can commence. After applying the adhesive powder, the design must be cured before it’s ready for transfer to fabric.

Once everything is prepared, heat and pressure combine to bond the print to the garment, producing vibrant, high-quality designs. For best results, users must follow the manufacturer’s guidelines regarding temperature, time, and pressure settings to achieve durable and professional-grade results.

The Future of DTF Transfers and Community Engagement

As DTF printing technology evolves, new developments are emerging that promise to enhance print durability and reduce the environmental impact of the process. Innovations in ink formulations are paving the way for even brighter colors and extended wash life, allowing creators to produce high-quality garments that withstand the test of time. This ensures that businesses can confidently market their products, knowing that they offer customers both style and longevity.

In addition to technological advancements, there is a robust community of DTF enthusiasts and professionals emerging online. Resources such as forums, tutorials, and social media groups provide valuable insights for newcomers seeking to learn and refine their skills. Engaging with this community fosters collaboration, allowing individuals to share tips, troubleshoot issues, and celebrate successes in their DTF printing journeys.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct to Film transfers, involve printing designs onto a special film that is then used to transfer the designs onto fabrics using heat and pressure. This method allows for vibrant, high-quality prints that can adhere to various materials, making it an ideal choice for custom apparel printing.

What are the advantages of using DTF printing in custom apparel?

DTF printing offers several advantages including versatility with different fabrics, high detail and color vibrancy, cost-effectiveness due to lower initial investments, and the ability to fulfill orders with no minimum quantities. This makes it an excellent choice for businesses and hobbyists looking to create unique designs.

How can I start using DTF transfers for my custom apparel?

To start using DTF transfers, you will need a DTF printer, transfer film, and heat press. Begin by creating your design, printing it onto the film, and then transferring it onto your chosen fabric using a heat press. This straightforward process makes it accessible for both beginners and experienced printers.

What types of fabrics can DTF printing be used on?

DTF printing is highly versatile and can be used on a wide range of fabrics. This includes cotton, polyester, nylon, blends, and even specialty fabrics. This compatibility allows for the creation of custom apparel that can cater to various needs and aesthetics.

Are DTF transfers cost-effective for small businesses?

Yes, DTF transfers are considered cost-effective for small businesses because they require less upfront investment compared to other printing methods like direct-to-garment (DTG) or screen printing. This allows small businesses to explore custom apparel printing without significant financial risk.

What recent advancements have been made in DTF transfers technology?

Recent developments in DTF transfers technology include improvements in ink formulations and adhesive technologies that enhance print durability and washability. These advancements ensure that DTF prints are long-lasting and can withstand regular wear, making them suitable for everyday apparel.

| Key Points | Description |

|---|---|

| What is DTF Printing? | DTF printing involves printing designs onto a unique film which is then transferred to fabrics using heat and pressure. |

| Versatility | Compatible with various fabrics like cotton, polyester, and blends, enabling diverse custom apparel. |

| High Detail and Vibrancy | Produces sharp prints with vibrant colors, capturing intricate designs effectively. |

| Cost-Effective | Lower upfront investment compared to other methods, making it accessible for small businesses. |

| No Minimum Orders | Allows printing as few as one piece at a time, perfect for customized offerings. |

| Recent Developments | Advancements in ink and adhesive technologies are enhancing durability and washability. |

| Community & Resources | An emerging community provides support through online resources, forums, and social groups. |

Summary

DTF transfers are revolutionizing custom apparel printing by providing a unique blend of versatility, vibrancy, and affordability. This innovative technique allows for high-quality designs on various types of fabrics, making it an essential tool for anyone in the printing industry. As technology evolves, so does the potential of DTF transfers, which are poised to become an even more integral part of modern printing solutions. Embracing DTF transfers opens up a world of creative opportunities for businesses and hobbyists alike.