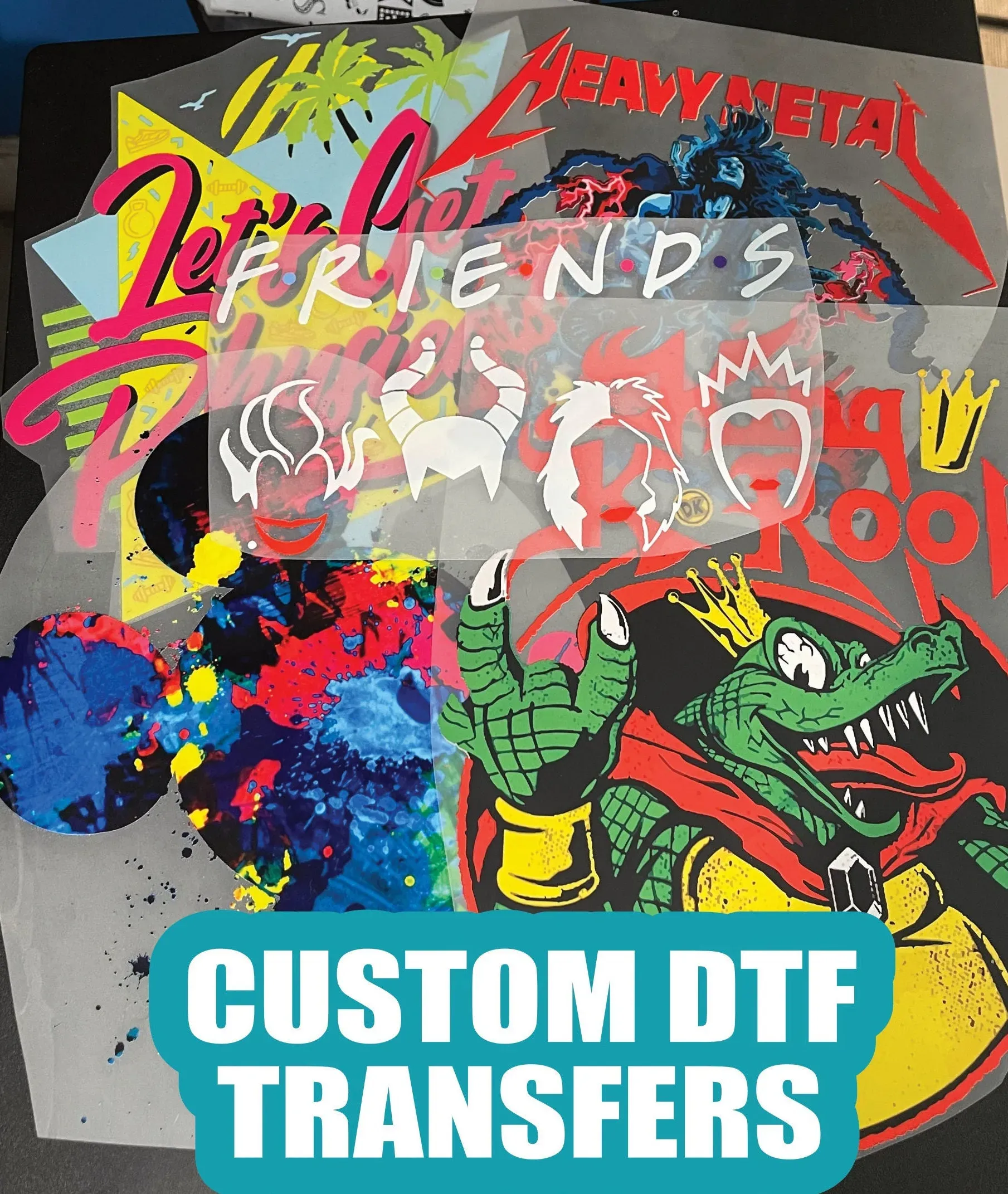

DTF transfers are transforming the landscape of apparel design, enabling creators to achieve vibrant and intricate graphics with unprecedented ease. Utilizing Direct-to-Film printing techniques, this innovative method allows artists to transfer detailed images directly onto various fabrics, making it a game-changer in the world of custom apparel. Whether you’re a seasoned designer or just starting out, DTF transfers offer a fantastic solution for bringing your creative visions to life. With the ability to print on both light and dark materials, this technology ensures that rich color vibrancy is maintained across all textiles. In this article, we will delve into the essential tools and techniques behind DTF transfers, exploring the latest printing innovations that are shaping the future of fashion.

Known for its efficiency and quality, DTF printing – or Direct-to-Film technique – is a cutting-edge approach to fabric decoration that streamlines the design process for custom garments. This printing method offers unparalleled versatility, allowing creators to produce high-resolution images that stand up to the rigors of wear while maintaining a soft touch. As this technology gains traction in the industry, it opens the door for personalized apparel options that cater to specific taste and style preferences. Designers are now equipped with the ability to create stunning visuals that not only look professional but also offer the highest level of durability. In this discussion, we will examine the fundamentals of DTF printing and highlight its many advantages over traditional methods.

Understanding DTF Transfers: The Future of Apparel Printing

Direct-to-Film (DTF) transfers are revolutionizing the apparel printing industry, allowing designers to produce vibrant graphics with remarkable precision. This printing method involves specially formulated inks that are transferred onto a film, which can then be applied to a variety of fabrics. One of the standout features of DTF transfers is their ability to maintain color intensity even on darker textiles, overcoming a significant limitation found in conventional printing methods like screen printing.

As apparel design continues to evolve, the demand for high-quality, detailed prints has surged. DTF transfers meet this need by offering flexibility – they can be used on cotton, polyester, blends, and even specialized fabrics. This versatility positions DTF printing as a reliable choice for custom apparel designers who want to explore creative graphics without compromising on quality.

Essential Equipment for Successful DTF Printing

To achieve stunning results with DTF transfers, selecting the right equipment is crucial. High-quality DTF printers are essential as they should have the capacity to produce a wide color gamut and fine details that elevate your designs. Before investing, it’s important to research various printer models that are optimized for DTF techniques.

In addition to printers, the choice of inks and DTF films significantly influences the final output. Water-based inks are highly recommended for DTF applications due to their brilliant colors and environment-friendly properties. Moreover, ensuring compatibility between the films and inks will maximize performance during the printing process.

Designing Eye-Catching Graphics for DTF Transfers

Creating standout designs is key to the success of any DTF printing project. Using vector graphics allows for scalability without loss of quality, which is essential when you are working on apparel designs that require precision. Tools such as Adobe Illustrator or CorelDRAW offer utilities specifically designed to enhance your creative process and help manage color schemes.

Effective color management is crucial in DTF printing. It’s advisable to perform color calibration with your printer and conduct test prints to ensure the vibrancy and accuracy of your designs. This attention to detail will set your creations apart from competitors and yield designs that resonate well with customers.

Expert Tips for Enhancing DTF Printing Quality

Industry experts emphasize the importance of pre-treating fabrics before applying DTF transfers, as this improves adhesion and durability of prints. By preparing the fabric surface, you ensure that your designs withstand wear and washing, which is vital for building a reputation in custom apparel.

Participating in workshops or online forums dedicated to DTF printing can provide invaluable insights. Many experienced creators share tips on troubleshooting common issues, offering creative solutions that can refine your processes and enhance the quality of your outputs.

Market Trends in DTF Printing and Custom Apparel

As the custom apparel market grows, DTF printing is becoming increasingly popular among small businesses and independent designers. The cost-effectiveness combined with the outstanding quality of prints makes DTF an attractive option for those looking to enter the industry. This trend indicates a shift towards personalization in the apparel design landscape, where consumers seek unique and tailored products.

Future projections suggest that as technology progresses, DTF printing methodologies will advance, opening up new possibilities in the realm of creative apparel design. Engaging with these trends not only keeps designers relevant but also enables them to fulfill the evolving demands of customers seeking distinctiveness in their fashion choices.

The Advantages of DTF Transfers Over Traditional Printing Methods

DTF transfers boast several advantages when compared to traditional printing methods, primarily in terms of feel and flexibility. The soft finish of DTF transfers enhances wearer comfort, making them appealing to those who prioritize quality in their apparel. Furthermore, DTF’s capability to print both light and dark inks broadens the scope of design opportunities.

In contrast to screen printing, which may require intricate setups for each color, DTF transfers simplify the process. This efficiency allows for more rapid production times, making it possible for designers to cater to large orders or intricate patterns without significant delays.

Frequently Asked Questions

What are DTF transfers and how do they work in apparel design?

DTF transfers, or Direct-to-Film transfers, are a printing method that involves printing designs onto a specially coated film. This film is then heat-pressed onto textiles, enabling vibrant colors and intricate details to be transferred onto various fabrics, including dark materials that are challenging for other techniques.

What advantages do DTF printing techniques offer over traditional printing methods?

DTF printing techniques provide significant advantages, including the ability to print on a variety of fabrics, particularly dark textiles, without losing color vibrancy. The process results in soft prints that feel comfortable on apparel, and it allows for the transfer of both white and colored inks, providing greater design flexibility.

What equipment is essential for successful DTF Transfers production?

For successful DTF Transfers, essential equipment includes a high-quality DTF printer with a wide color gamut, water-based DTF inks for vibrant colors, compatible DTF transfer films, and a reliable heat press with adjustable settings to ensure proper adhesion to textiles.

How can I enhance the quality of my DTF Transfers designs?

To enhance the quality of your DTF Transfers designs, utilize vector graphics to maintain clarity, manage colors effectively by using appropriate profiles, and test different materials to determine the best heat press settings for optimal adhesion and durability.

Are DTF transfers suitable for custom apparel production?

Yes, DTF transfers are highly suitable for custom apparel production. They allow creators to produce detailed and vibrant designs tailored to individual preferences, making them an excellent choice for businesses looking to offer personalized merchandise in the growing custom apparel market.

What is the future of DTF printing in the apparel industry?

The future of DTF printing in the apparel industry looks promising, with increasing adoption among small businesses due to its cost-effectiveness and high-quality output. As personalization becomes more popular, advancements in DTF technology are expected to enhance user engagement and expand applications in custom apparel design.

| Aspect | Details |

|---|---|

| Introduction | DTF transfers simplify achieving professional designs for apparel. |

| What are DTF Transfers? | An innovative printing process using special films that adhere to fabrics, producing vibrant colors, especially on dark textiles. |

| Essential Equipment | 1. DTF Printers: Must be high-quality. 2. Inks & Films: Water-based inks recommended. 3. Heat Presses: Essential for correct adhesion and durability. |

| Design Techniques | 1. Use Vector Graphics for quality. 2. Color Management is crucial. 3. Material Testing helps determine best practices for various fabrics. |

| Industry Insights | Pre-treating fabrics for better adhesion; engage with expert communities for guidance. |

| Market Trends | DTF printing is growing among small businesses, focusing on customization and personalization. |

| Advantages of DTF over Other Methods | Softer print feel, ability to transfer white/light inks, and overall flexibility. |

Summary

DTF Transfers are revolutionizing the world of custom apparel printing by making it accessible and efficient for designers and businesses alike. With a combination of specialized equipment, materials, and techniques, anyone can achieve stunning results that enhance their clothing designs. As the market adapts towards personalization and customization, DTF transfers provide a unique solution that stands out among traditional printing methods. Designers embracing this innovative technology can expect to expand their creative possibilities, while businesses can cater to a growing customer demand for unique and vibrant apparel. Engaging with DTF communities allows for ongoing learning and improvement, ensuring that creators stay at the forefront of this exciting trend in garment decoration.