DTF transfers, short for Direct-to-Film transfers, are swiftly redefining the realm of custom apparel printing, providing a fresh and innovative approach to fabric decoration. By utilizing DTF printing technology, creators can achieve vibrant colors and intricate designs on various textiles with ease, perfect for beginners navigating the world of printing. This comprehensive guide delves into the advantages of DTF, highlighting how this method streamlines the DTF transfer process while maintaining exceptional quality. Whether you’re looking to produce personalized garments or simply explore this emerging technique, understanding DTF transfers opens up remarkable opportunities in the textile printing market. Join us as we highlight the key benefits of DTF printing, and walk you through the essential steps to get started.

Direct-to-Film printing, often referred to as DTF, represents a cutting-edge technique in the fabric printing industry that is gaining traction among both seasoned professionals and novices. This innovative method allows for intricate designs to be printed directly onto a specially prepared film, which is subsequently transferred onto fabric using a heat press. With its myriad of advantages, including adaptability to different textiles and cost-effectiveness, DTF printing is making customized apparel accessible to a broader audience. Known by various names, such as DTF printing for beginners, this method is perfect for those seeking to harness the potential of modern printing technologies. As we explore this thrilling realm, you’ll discover practical insights and expert tips on effectively utilizing DTF transfers to maximize your design impact.

Understanding DTF Printing: A Beginner’s Guide

Direct-to-Film (DTF) printing represents a significant advancement in the realm of custom apparel printing. As a beginner, it’s essential to grasp the fundamentals of this innovative technology. DTF involves printing designs onto a special film, which are then used to transfer high-quality graphics onto textiles. This method distinguishes itself from traditional printing techniques like screen printing by offering vibrant colors and intricate details that can elevate your designs. Understanding these foundational aspects sets the stage for exploring DTF’s numerous benefits in the custom apparel market.

For newcomers looking to harness the potential of DTF printing, grasping the essential techniques and equipment involved is crucial. You’ll need not just a DTF printer and a heat press but also high-quality inks and films specially designed for the process. This knowledge empowers you to start your journey confidently, allowing you to experiment with various designs and fabrics while gaining practical insights into effective printing practices. As you delve into DTF printing, keep an open mind and embrace the learning curve that comes with mastering this exciting technology.

The DTF Transfer Process Explained

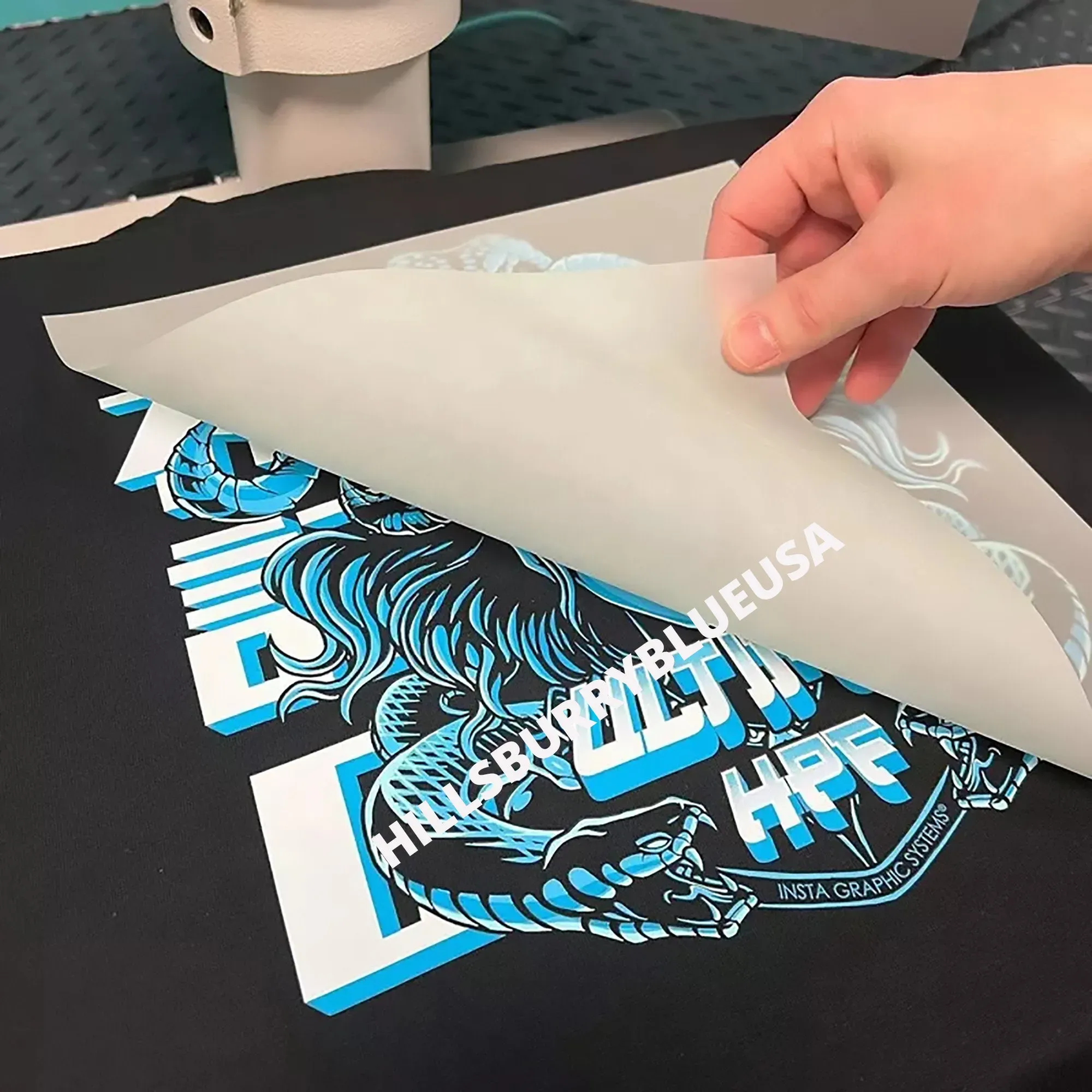

Understanding the DTF transfer process is pivotal for anyone new to this vibrant printing method. The process begins with printing your unique designs onto a release film using specialized DTF inks that offer exceptional quality and color accuracy. The printed film is then treated with a hot-melt adhesive powder, which is crucial for ensuring the design adheres well to the fabric once heat is applied. This two-step application of ink and adhesive distinguishes DTF printing from other processes, ensuring that designs come out rich and durable.

Following the application of adhesive, the next steps involve curing and transferring the design onto the chosen fabric using a heat press. The heat activates the adhesive, bonding the design securely to fabrics ranging from cotton to polyester. This versatility is a major benefit of DTF printing, making it suitable for various apparel items, from t-shirts to hoodies. By mastering the intricacies of the DTF transfer process, beginners can ensure quality and longevity in their printed designs.

Benefits of Choosing DTF Transfers

One of the standout advantages of DTF transfers is the exceptional quality they deliver. Unlike traditional methods which may compromise on vibrancy or detail, DTF printing produces stunning graphics characterized by robust colors and intricate designs. This capability allows for creativity without limitation, making DTF a favored choice among custom apparel creators who seek to produce eye-catching merchandise. The ability to handle complex patterns or designs makes DTF printing a valuable asset for small business owners and hobbyists alike.

Another key benefit of DTF transfers lies in their versatility. DTF technology is not limited to one type of fabric; instead, it can be used effectively across a range of materials including cotton, polyester, and blends. This broad compatibility opens up opportunities for creating a diverse collection of customized apparel, catering to various customer preferences and needs. For beginners venturing into the printing business, this adaptability provides a significant advantage, allowing for experimentation and creative expression across different fabric types.

Navigating Recent Developments in DTF Technology

The DTF printing sector is witnessing rapid growth and innovation, influenced by the increasing demand for personalized apparel. Market trends indicate that customization is no longer a niche; rather, it is becoming mainstream, prompting businesses to adopt DTF technology for efficient and affordable production. Staying informed about these developments is critical for beginners, as the right tools and techniques can optimize productivity and output quality. Innovations in printing equipment and inks are continuously emerging, transforming the landscape of DTF printing.

Additionally, there is a noticeable push towards sustainability within the DTF printing industry. Many manufacturers are focusing on eco-friendly materials and inks, aiming to reduce the environmental impact of printing processes. This shift towards sustainability resonates with today’s consumers who increasingly prioritize ethical practices in their purchasing decisions. For newcomers, embracing these sustainable practices can not only set your brand apart but also align your efforts with the growing market trend towards environmentally-conscious production.

Practical DTF Printing Tips for Beginners

Starting out in DTF transfers can feel daunting, but with the right approach, you can simplify the learning process. One of the most important practical tips is to invest in high-quality equipment, especially when selecting your DTF printer and heat press. Research various brands and models to find equipment that meets your needs and budget. Ensuring that you have reliable tools not only enhances your productivity but also positively impacts the quality of your printed designs.

In addition to equipment, understanding fabric compatibility is essential for successful DTF printing. While this technique works well on a range of materials, conducting tests on fabric samples prior to large runs is crucial. This practice helps identify which fabrics yield the best results for your designs. Furthermore, becoming proficient with graphic design software can significantly improve your outcomes, as it allows for detailed customization and high-quality prints that accurately reflect your creative vision.

Future of DTF Printing in Custom Apparel

As the world of custom apparel continues to evolve, the future of DTF printing looks promising. With ongoing advancements in printing technology and materials, we can expect even greater efficiencies and capabilities in producing intricate designs. DTF printing offers businesses a competitive edge, enabling them to meet consumer demands for quick turnaround times and high-quality products. For beginners entering this field, staying abreast of trends and embracing new technologies will be key to thriving in this dynamic industry.

Moreover, as customization becomes increasingly popular, DTF printing is poised to become a significant player in the custom apparel market. The ability to produce vibrant, high-quality graphics on diverse fabrics makes DTF an attractive option for entrepreneurs. As consumer preferences shift towards unique and personalized experiences, harnessing the power of DTF technology can help new businesses capture attention and build loyalty in a crowded marketplace.

Frequently Asked Questions

What is the DTF transfer process and how does it work?

The DTF transfer process consists of printing a design onto a specialized release film using DTF inks, applying a hot-melt adhesive powder, and curing it with heat. Finally, the design is transferred to a fabric using a heat press, activating the adhesive to bond the print to the garment.

What are the key advantages of using DTF printing for custom apparel?

DTF printing offers several advantages, including exceptional print quality with vibrant colors, versatility across various fabrics, cost-effectiveness for small orders, and user-friendly technology, making it ideal for beginners and small businesses.

Can DTF transfers be used on any type of fabric?

Yes, DTF transfers can be applied to a wide range of fabrics, including cotton, polyester, and blends. However, it’s crucial to test your designs on different fabric samples to ensure compatibility and desired results.

How is DTF printing different from traditional screen printing?

DTF printing differs from traditional screen printing in that it allows for high-quality prints with multiple colors without the need for screens. This method is more flexible and cost-effective, particularly for smaller runs or custom designs.

What equipment do beginners need to get started with DTF transfers?

Beginners need to invest in a reliable DTF printer, high-quality heat press, and compatible DTF inks and release films. Familiarity with design software also enhances the ability to create high-quality graphics for printing.

Are there any sustainability initiatives within the DTF printing industry?

Yes, sustainability is becoming increasingly important in the DTF printing industry, with manufacturers focusing on eco-friendly inks and materials, as well as improving production methods to reduce environmental impact.

| Key Point | Description |

|---|---|

| Definition | DTF transfer printing involves applying ink directly onto a coated film, which is then transferred to fabric using heat. |

| Process Overview | The DTF process includes printing, adhesive application, curing, and heat press transfer, ensuring quality outcomes. |

| Advantages | DTF transfers offer exceptional print quality, fabric versatility, cost-effectiveness, and user-friendly technology. |

| Market Growth | The DTF market is expanding, driven by a rise in personalization demand and advancements in printing technology. |

| Sustainability Initiatives | DTF manufacturers are focusing on eco-friendly inks and materials to reduce environmental impact. |

| Technological Innovations | New developments are refining the DTF process with enhanced print speeds, color accuracy, and advanced software. |

| Tips for Beginners | Invest in quality equipment, understand fabric compatibility, enhance design software skills, and perfect adhesive application. |

Summary

DTF transfers are transforming the landscape of textile printing and customization. This innovative method provides unparalleled quality, adaptability across various fabric types, and a cost-effective solution for those venturing into personalized apparel. As the popularity of DTF transfers continues to rise, it opens doors for beginners to experiment with creativity in their designs. Taking advantage of the latest technological advancements and sustainable practices will not only enhance your printing capabilities but also align your creations with the trends of a conscious market. Embrace the artistry of DTF transfers and bring your unique visions to life!