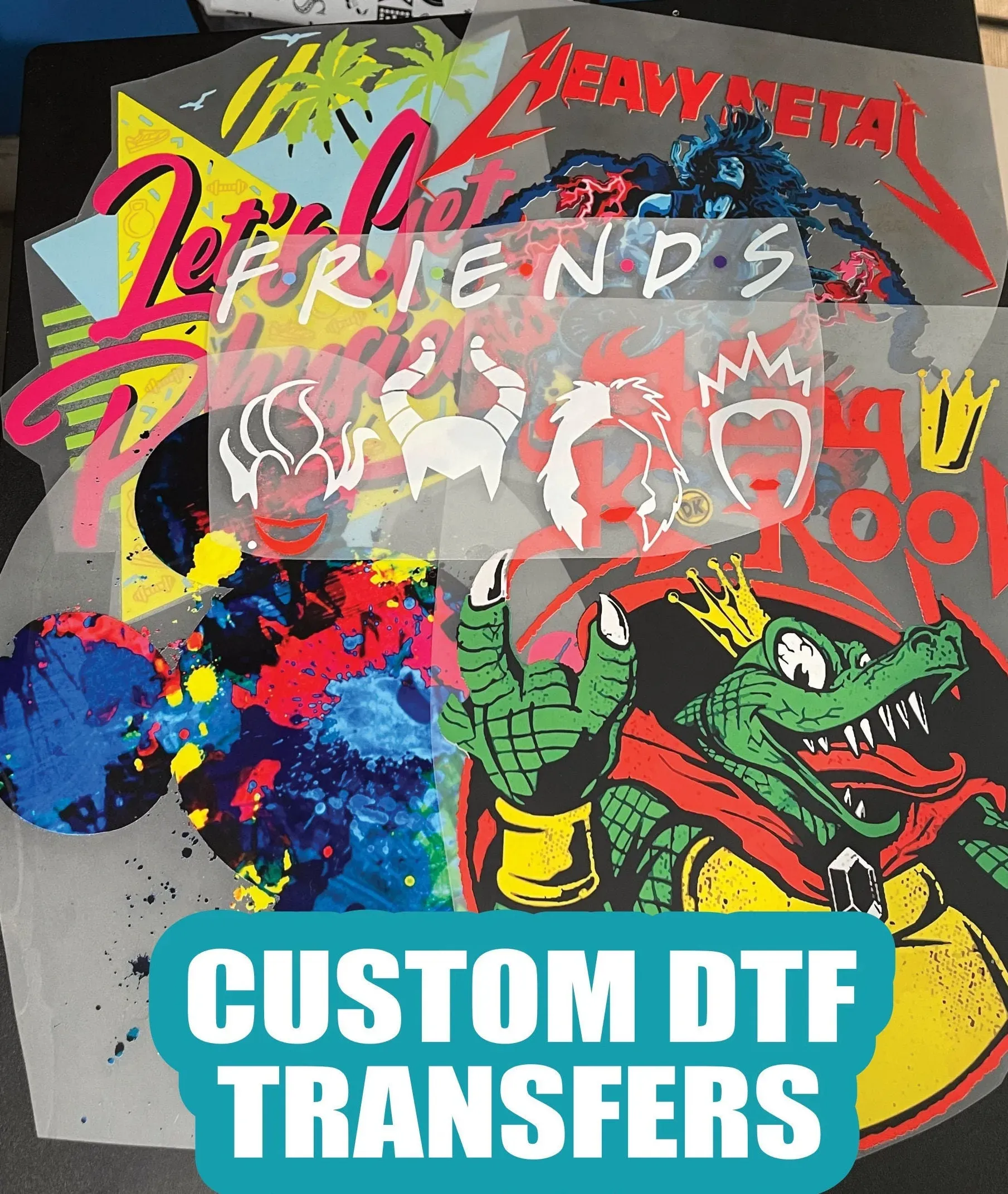

DTF Transfers, or Direct to Film transfers, are revolutionizing the world of fabric printing techniques, offering creators a way to produce vivid and durable designs with relative ease. This innovative printing method involves transferring high-resolution images onto films that are then heat-pressed onto various fabrics, making it a popular choice for custom apparel and promotional items. However, for beginners diving into this exciting realm, understanding the common DTF transfer mistakes is crucial to achieving outstanding results. In this guide, we’ll break down these errors, empowering you with the knowledge to enhance your DTF printing experience. Get ready to unlock the full potential of your creativity with expert insights into the often-overlooked aspects of DTF printing, ensuring every project shines vibrant and professional.

Direct to Film (DTF) printing strategies have gained much attention among fabric printing enthusiasts due to their flexibility and quality outcomes. This fabric printing technique allows for the seamless application of colorful designs onto clothing, accessories, and more, making it an attractive option for those looking to start a side business or refine their craft. Within this introduction to DTF transfers, we will explore essential tricks and traps that beginners may encounter, allowing you to navigate this creative journey with confidence. From printer settings to transfer preparation, understanding the process will help you avoid common pitfalls and achieve superior prints. Explore how these direct film transfers can transform your artwork into high-quality, lasting impressions.

Understanding DTF Transfers: The Basics

Direct to Film (DTF) transfers have emerged as a revolutionary technique in fabric printing, bridging the gap between traditional methods and modern technology. This approach involves printing a design onto a specific film that is coated with an adhesive powder. When heat is applied through a heat press, the design transfers seamlessly onto the fabric. This method has become popular due to its versatility, allowing users to print on various materials, including cotton, polyester, and blends, resulting in vibrant graphics that stand out.

As mentioned, DTF printing utilizes specialized printers that are tailored for the process. This not only includes the right type of ink but also specific settings that must be adjusted to optimize the print quality. Beginners often confuse DTF with other fabric printing techniques like screen printing or heat transfer vinyl (HTV), but the nuances in the preparation and execution make DTF a unique option for custom apparel.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF Transfers, or Direct to Film transfers, involve printing designs onto a special film, applying adhesive powder, and then utilizing a heat press to transfer the design onto fabric. This printing technique is favored for its vibrant colors and durability, making it ideal for custom apparel.

What should beginners know about DTF printing mistakes?

Beginners in DTF printing should be cautious of common mistakes such as using poor-quality films, incorrect printer settings, and neglecting to conduct test transfers on scrap fabric. These errors can affect the print quality and adhesion, leading to unsatisfactory results.

How can I ensure quality in my DTF transfers?

To ensure quality in DTF transfers, always use high-quality transfer films suitable for your printer, adjust your printer settings correctly, and pre-wash the fabric to enhance adhesion. Proper heat press parameters and allowing adequate curing time are also crucial for achieving durable prints.

What are common DTF transfer mistakes to avoid?

Common DTF transfer mistakes include under-preparing the garment, ignoring heat press settings, and failing to allow proper curing time. Additionally, not testing transfers before production can lead to failed prints that may require redoing and waste materials.

What is the importance of heat press parameters in DTF transfers?

Heat press parameters, including temperature and pressure, are vital in DTF transfers as they determine the success of adhesion between the print and fabric. Ignoring these parameters can result in incomplete transfers or damaged prints.

What maintenance is required for DTF printers?

Regular maintenance for DTF printers includes cleaning printer heads to prevent clogging and ensuring that inks are stored properly to maintain quality. Neglecting printer maintenance can lead to inconsistent print results and operational issues.

| Key Points | Description |

|---|---|

| What are DTF Transfers? | DTF transfers involve printing designs on film, applying adhesive powder, and transferring to fabric using heat press. |

| Common Mistakes | 1. Choosing Poor-Quality Films: Leads to faded colors and less durable prints. 2. Inadequate Printer Settings: Incorrect settings can lower print quality. 3. Not Testing Transfers: Skipping test runs may yield disappointing results. 4. Over or Under Prepping the Garment: Proper prep ensures good adhesion. 5. Ignoring Heat Press Parameters: Exact settings are crucial to avoid print damage. 6. Not Allowing Proper Curing Time: Insufficient curing leads to peeling prints. 7. Neglecting Maintenance: Regular upkeep prevents print quality issues. 8. Not Utilizing Correct Adhesive Powder: Inadequate use affects adhesion. |

| Conclusion | Understanding the pitfalls in DTF transfers can enhance your printing experience, focusing on quality materials and adherence to guidelines ensures success. |

Summary

DTF Transfers are an innovative method of printing images onto fabric that have gained popularity among hobbyists and small businesses alike. By avoiding common mistakes, you can enhance the quality of your prints and create stunning designs. It’s essential to prioritize high-quality materials, carefully adjust printer settings, and ensure proper garment preparation to achieve the best results. Additionally, taking the time to test transfers and allowing the correct curing time will further improve the durability and vibrancy of your prints. With the right knowledge and practice, you can master DTF transfers and take your custom apparel projects to the next level.